Product Description

INCOLOY alloy 945X (UNS N09945) offers enhanced strength over that of INCOLOY alloy 945. With increased levels of hardeners in the alloy composition, alloy 945X exhibits a minimum yield strength of 140 ksi. With this higher strength, alloy 945X is especially well suited for high strength oilfield equipment as both bar and mechanical tube products. The corrosion resistance of INCOLOY alloy 945X is comparable to that of INCOLOY alloy 945. Both alloys are approved to NACE MR0175 Level VII and Level VI-450°F. Thus, alloys 945 and 945X find applications in corrosive sour oil and gas environments containing hydrogen sulfide, free-sulfur, carbon dioxide, chlorides and other aggressive corrodents.

STANDARD PRODUCT FORMS

Bar, forging stock, tubes.

MAJOR SPECIFICATIONS

UNS 09945

NACE MR0175 (Approved to Level VII and Level VI at 450°F)

NACE MR0175 (Approved to Level VII and Level VI at 450°F)

LIMITING CHEMICAL COMPOSITION, %

Ni ......45.0 – 55.0

Cr......19.5 – 23.0

Fe............Balance

Mo..........3.0 – 4.0

Cu..........1.5 – 3.0

Nb..........2.5 – 4.5

Ti............0.5 – 2.5

Al......... 0.01 – 0.7

C..... 0.005 – 0.04

Mn.......... 1.0 max.

Si............ 0.5 max.

P............0.03 max.

S........ 0.030 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.281

g/cm3....................................................................... 7.777

Melting Range, °F...................................................2317 – 2510

°C...................................................1270 – 1377

Permeability at 200 Oersted.............................................1.003

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C).................... 7.88 (14.19)

70-800°F (21-427°C).................8.40 (15.12)

70-1200°F (21-649°C)...............8.85 (15.93)

g/cm3....................................................................... 7.777

Melting Range, °F...................................................2317 – 2510

°C...................................................1270 – 1377

Permeability at 200 Oersted.............................................1.003

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C).................... 7.88 (14.19)

70-800°F (21-427°C).................8.40 (15.12)

70-1200°F (21-649°C)...............8.85 (15.93)

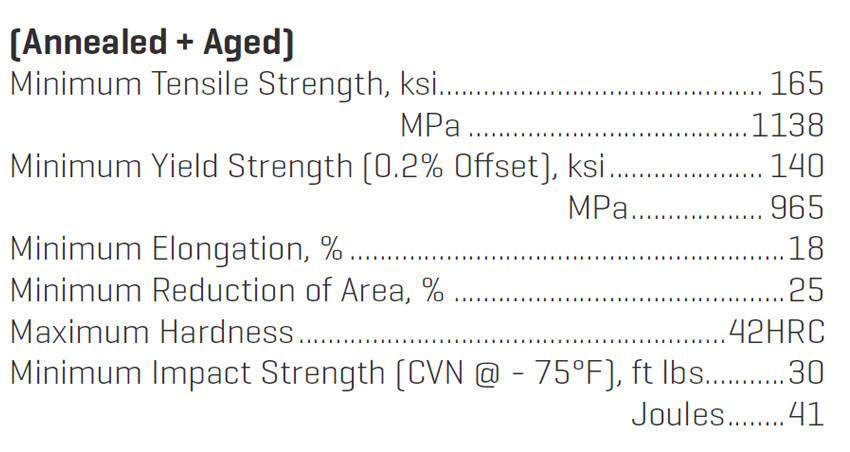

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message