Product Description

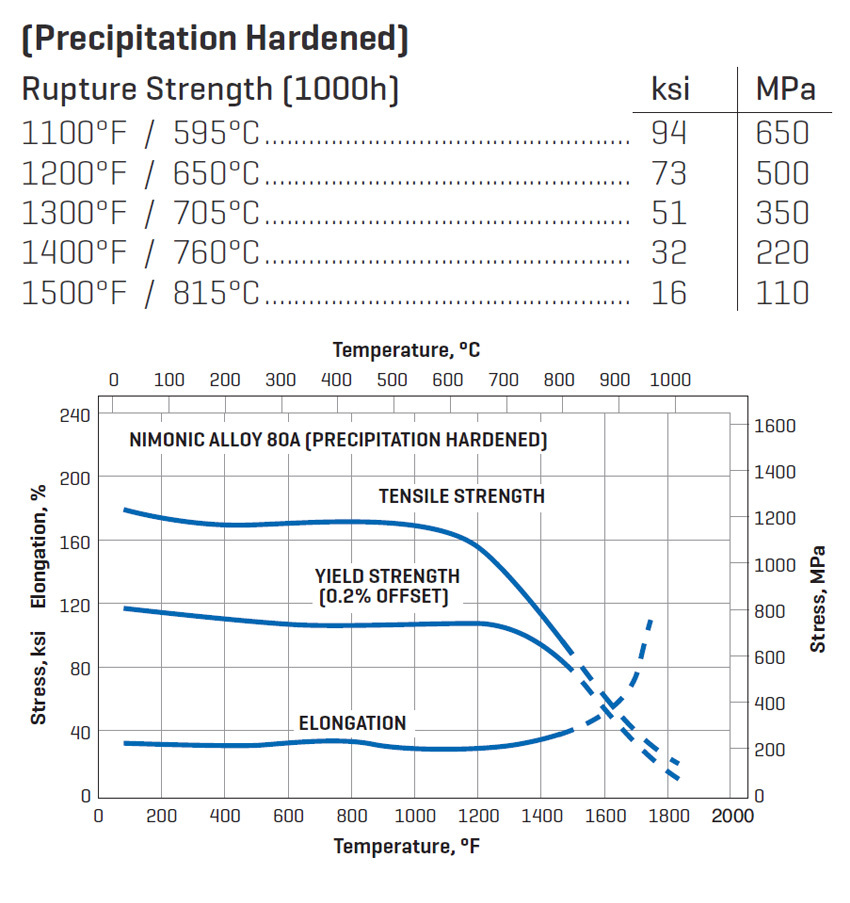

A nickel-chromium alloy similar to NIMONIC alloy 75 but made precipitation hardenable by additions of aluminum and titanium. The alloy has good corrosion and oxidation resistance and high tensile and creep-rupture properties at temperatures to 1500°F (815°C). Used for gas-turbine components (blades, rings and discs), bolts, tube supports in nuclear steam generators, die-casting inserts and cores, and exhaust valves in internal-combustion engines.

STANDARD PRODUCT FORMS

Sheet, round bar, flat bar, forging stock, hexagon, wire,

extruded section and plate.

extruded section and plate.

MAJOR SPECIFICATIONS

UNS N07080

BS 3076 (NA20), HR1,

HR201, HR401, HR601

ASTM B 637

AIR 9165-37

DIN 17742

Werkstoff Nr. 2.4952, 2.4631

AECMA Pr EN 2188 – 2191,

2396, 2397

BS 3076 (NA20), HR1,

HR201, HR401, HR601

ASTM B 637

AIR 9165-37

DIN 17742

Werkstoff Nr. 2.4952, 2.4631

AECMA Pr EN 2188 – 2191,

2396, 2397

LIMITING CHEMICAL COMPOSITION, %

Ni........Remainder

Cr.......18.0 – 21.0

Ti............1.8 – 2.7

Al............1.0 – 1.8

C...........0.10 max.

Si............ 1.0 max.

Cu.......... 0.2 max.

Fe........... 3.0 max.

Mn.......... 1.0 max.

Co........... 2.0 max.

B........ 0.008 max.

Zr..........0.15 max.

S........ 0.015 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.296

g/cm3......................................................................... 8.19

Melting Range, °F...................................................2410 – 2490

°C...................................................1320 – 1365

Specific Heat, Btu/lb•°F.....................................................0.107

J/kg•°C............................................................ 448

Permeability at 200 Oersted (15.9 kA/m).................. 1.0006

Coefficient of Expansion, 68 – 212°F, 10-6 in/in •°F........ 7.1

20 – 100°C, μm/m • °C.......... 12.7

Thermal Conductivity, Btu • in/ft2•h•°F............................77.7

W/m • °C.......................................... 11.2

Electrical Resistivity, ohm •circ mil/ft................................ 746

μΩ•m................................................. 1.24

g/cm3......................................................................... 8.19

Melting Range, °F...................................................2410 – 2490

°C...................................................1320 – 1365

Specific Heat, Btu/lb•°F.....................................................0.107

J/kg•°C............................................................ 448

Permeability at 200 Oersted (15.9 kA/m).................. 1.0006

Coefficient of Expansion, 68 – 212°F, 10-6 in/in •°F........ 7.1

20 – 100°C, μm/m • °C.......... 12.7

Thermal Conductivity, Btu • in/ft2•h•°F............................77.7

W/m • °C.......................................... 11.2

Electrical Resistivity, ohm •circ mil/ft................................ 746

μΩ•m................................................. 1.24

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message