Product Description

A precipitation-hardenable nickel-cobaltchromium alloy with an addition of molybdenum for solid-solution strengthening. The relatively high aluminum content enhances both strength (through greater precipitation hardening) and oxidation resistance. The alloy has high creep-rupture properties at temperatures to about 1740°F (950°C). Used in gas turbines for blades, discs and shafts.

STANDARD PRODUCT FORMS

Round and extruded section.

MAJOR SPECIFICATIONS

BS HR3, Werkstoff Nr. 2.4634, AECMA Pr EN 2179 – 2181

LIMITING CHEMICAL COMPOSITION, %

Ni .......Remainder

Co .....18.0 – 22.0

Cr ......14.0 – 15.7

Mo .........4.5 – 5.5

Ti ...........0.9 – 1.5

Al ...........4.5 – 4.9

C ..........0.12 max.

Si ...........1.0 max.

Cu..........0.2 max.

Fe ..........1.0 max.

Mn .........1.0 max.

S .......0.010 max.

B ...0.003 – 0.010

Zr .........0.15 max.

Co .....18.0 – 22.0

Cr ......14.0 – 15.7

Mo .........4.5 – 5.5

Ti ...........0.9 – 1.5

Al ...........4.5 – 4.9

C ..........0.12 max.

Si ...........1.0 max.

Cu..........0.2 max.

Fe ..........1.0 max.

Mn .........1.0 max.

S .......0.010 max.

B ...0.003 – 0.010

Zr .........0.15 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3 ........................................................................0.289

g/cm3 .........................................................................8.01

Melting Range, °F ...................................................2350 – 2450

°C ...................................................1290 – 1345

Specific Heat, Btu/lb • °F ....................................................0.100

J/kg • °C ...........................................................419

Permeability at 200 Oersted (15.9 kA/m) .................1.0007

Coefficient of Expansion, 68 – 212°F, 10-6 in/in • °F........6.8

20 – 100°C, µm/m • °C .........12.2

Thermal Conductivity, Btu • in/ft2 • h • °F ........................75.51

W/m • °C ........................................10.89

Electrical Resistivity, ohm • circ mil/ft ...............................788

µ Ω• m ................................................1.31

g/cm3 .........................................................................8.01

Melting Range, °F ...................................................2350 – 2450

°C ...................................................1290 – 1345

Specific Heat, Btu/lb • °F ....................................................0.100

J/kg • °C ...........................................................419

Permeability at 200 Oersted (15.9 kA/m) .................1.0007

Coefficient of Expansion, 68 – 212°F, 10-6 in/in • °F........6.8

20 – 100°C, µm/m • °C .........12.2

Thermal Conductivity, Btu • in/ft2 • h • °F ........................75.51

W/m • °C ........................................10.89

Electrical Resistivity, ohm • circ mil/ft ...............................788

µ Ω• m ................................................1.31

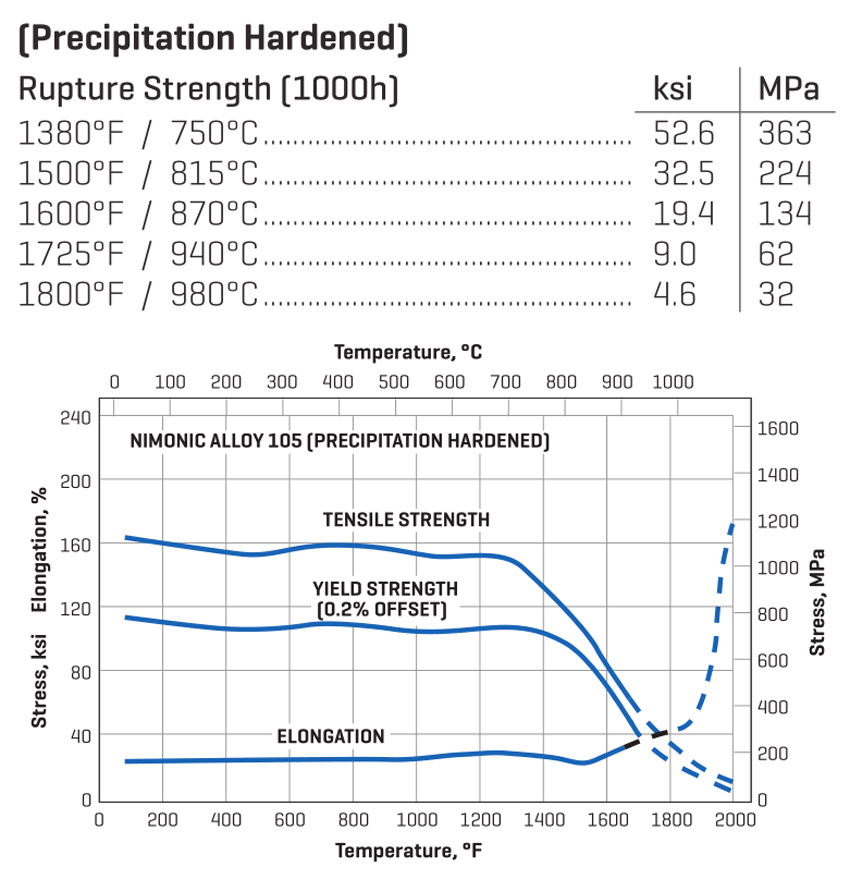

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message