Product Description

A cobalt-base alloy with excellent high temperature strength and good oxidation resistance to 2000°F (1093°C). The high chromium level coupled with small additions of lanthanum produce an extremely tenacious and protective scale. The alloy also has good sulfidation resistance and excellent metallurgical stability displayed by its ductility after prolonged exposure to elevated temperatures. Fabricability and weldability combine to make the alloy useful in typical gas turbine applications such as combustors, flame holders, liners and transition ducts.

STANDARD PRODUCT FORMS

Forging billet, bar, plate, and sheet.

MAJOR SPECIFICATIONS

UNS R30188, AMS 5608, AMS 5772

LIMITING CHEMICAL COMPOSITION, %

Limiting

C .......0.05 – 0.15

Mn .......1.25 max.

Si ...........0.2 – 0.5

Cr ......20.0 – 24.0

Ni ......20.0 – 24.0

W ......13.0 – 16.0

La .....0.02 – 0.12

Fe ..........3.0 max.

Co ...........Balance

B .......0.015 max.

C .......0.05 – 0.15

Mn .......1.25 max.

Si ...........0.2 – 0.5

Cr ......20.0 – 24.0

Ni ......20.0 – 24.0

W ......13.0 – 16.0

La .....0.02 – 0.12

Fe ..........3.0 max.

Co ...........Balance

B .......0.015 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3 ........................................................................0.330

g/cm3 .........................................................................9.13

Melting Range, °F ...................................................2375 – 2425

°C ...................................................1300 – 1330

Specific Heat, Btu/lb • °F ....................................................0.097

J/kg • °C ...........................................................405

Coefficient of Expansion, 70 – 200°F, 10-6 in/in • °F........6.6

21 – 93°C, µm/m • °C ............11.9

Thermal Conductivity, Btu • in/ft2 • h • °F ..............................84

W/m • °C..........................................12.1

g/cm3 .........................................................................9.13

Melting Range, °F ...................................................2375 – 2425

°C ...................................................1300 – 1330

Specific Heat, Btu/lb • °F ....................................................0.097

J/kg • °C ...........................................................405

Coefficient of Expansion, 70 – 200°F, 10-6 in/in • °F........6.6

21 – 93°C, µm/m • °C ............11.9

Thermal Conductivity, Btu • in/ft2 • h • °F ..............................84

W/m • °C..........................................12.1

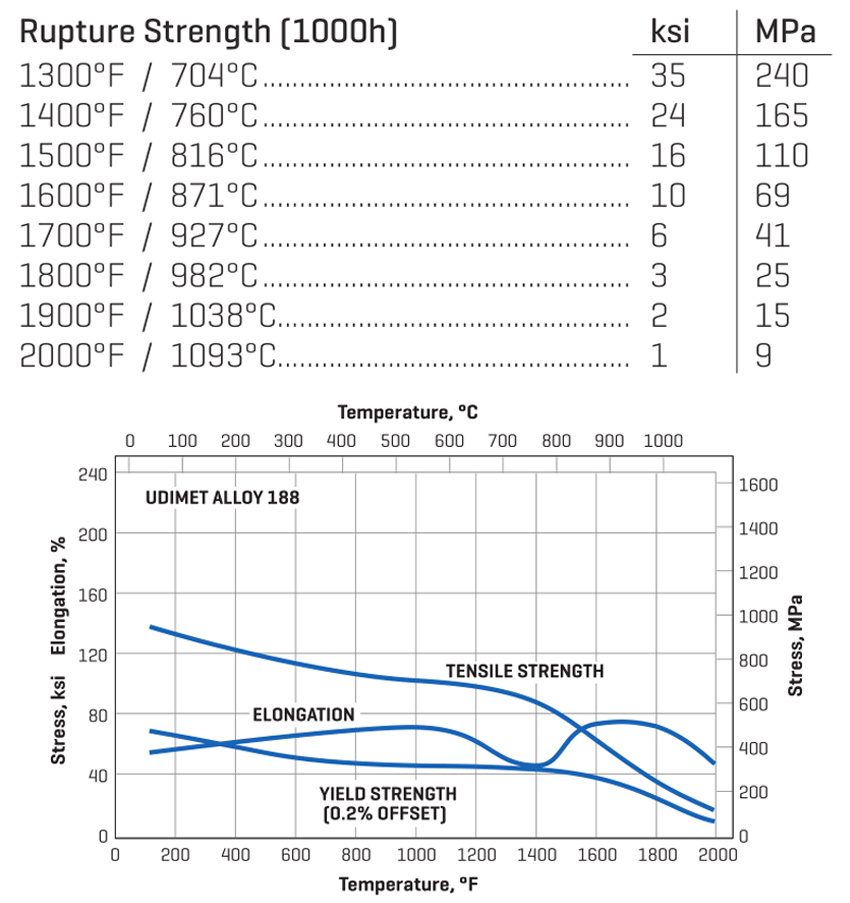

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message

SHANGHAI KANGSHENG AVIATION MATERIALS TECHNOLOGY CO., LTD.

Address: No. 5999, Huyi Road, Waigang Town, Jiading District, Shanghai

Tel:13641813331

Technical support:13671903676

Emial:ksalloy@ksalloy.com

Copyright: 2022 Shanghai Kangsheng Aviation Materials Technology Co., Ltd.

Powered By:www.300.cn SEO