Product Description

INCONEL alloy 706 is a precipitation-hardenable nickel-iron-chromium alloy that provides high mechanical strength in combination with good fabricability. The properties of the alloy are similar to those of INCONEL alloy 718 (N07718) except that alloy 706 is more readily fabricated, particularly by machining. Primary uses of the alloy are aerospace and land-based gas turbine parts and components, requiring resistance to creep, and stress rupture up to 1300˚F (704˚C), oxidation resistance and good fabricability.

STANDARD PRODUCT FORMS

Round bar and forging stock.

MAJOR SPECIFICATIONS

UNS N09706,SAE AMS 5605, 5606, 5701 – 5703

LIMITING CHEMICAL COMPOSITION, %

Nia......39.0 – 44.0

Cr....... 14.5 – 17.5

Fe.......Remainder

Nbb.........2.5 – 3.3

aPlus Co. bPlus Ta.

Ti............1.5 – 2.0

Al..........0.40 max.

C...........0.06 max.

Cu........0.30 max.

Mn........0.35 max.

S........ 0.015 max.

Si..........0.35 max.

P......... 0.020 max.

B........ 0.006 max.

Co.........1.00 max.

Cr....... 14.5 – 17.5

Fe.......Remainder

Nbb.........2.5 – 3.3

aPlus Co. bPlus Ta.

Ti............1.5 – 2.0

Al..........0.40 max.

C...........0.06 max.

Cu........0.30 max.

Mn........0.35 max.

S........ 0.015 max.

Si..........0.35 max.

P......... 0.020 max.

B........ 0.006 max.

Co.........1.00 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3 (g/cm3)............................................0.291 (8.05)

Melting Range, °F (°C)..............2434 – 2499 (1334 – 1371)

Specific Heat, Btu/lb•°F (J/kg•°C).......................0.106 (444)

Curie Temperature, °F (°C)....................................<-109 (-78)

Permeability at 200 Oersted (15.9 kA/m).....................1.011

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21–93°C)......................7.40 (13.3)

70-500°F (21–260°C).................. 8.25 (14.9)

70-800°F (21–427°C).................. 8.57 (15.4)

70-1000°F (21–538°C)................ 8.73 (15.7)

70-1200°F (21–650°C)................ 8.97 (16.2)

Thermal ConductivityA, Btu•in/ft2•h•°F.....................................87

W/m•°C.............................................. 12.5

Electrical ResistivityA, ohm•circ mil/ft...................................592

μΩ•m................................................ 0.985

Young’s ModulusA, 106 psi (GPa)............................ 30.4 (210)

Shear’s ModulusA, 106 psi (GPa)................................11.0 (76)

Poisson’s RatioA.....................................................................0.382

HardnessA, HRC.................................................................36 – 42

ARoom temperature, as aged.

Melting Range, °F (°C)..............2434 – 2499 (1334 – 1371)

Specific Heat, Btu/lb•°F (J/kg•°C).......................0.106 (444)

Curie Temperature, °F (°C)....................................<-109 (-78)

Permeability at 200 Oersted (15.9 kA/m).....................1.011

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21–93°C)......................7.40 (13.3)

70-500°F (21–260°C).................. 8.25 (14.9)

70-800°F (21–427°C).................. 8.57 (15.4)

70-1000°F (21–538°C)................ 8.73 (15.7)

70-1200°F (21–650°C)................ 8.97 (16.2)

Thermal ConductivityA, Btu•in/ft2•h•°F.....................................87

W/m•°C.............................................. 12.5

Electrical ResistivityA, ohm•circ mil/ft...................................592

μΩ•m................................................ 0.985

Young’s ModulusA, 106 psi (GPa)............................ 30.4 (210)

Shear’s ModulusA, 106 psi (GPa)................................11.0 (76)

Poisson’s RatioA.....................................................................0.382

HardnessA, HRC.................................................................36 – 42

ARoom temperature, as aged.

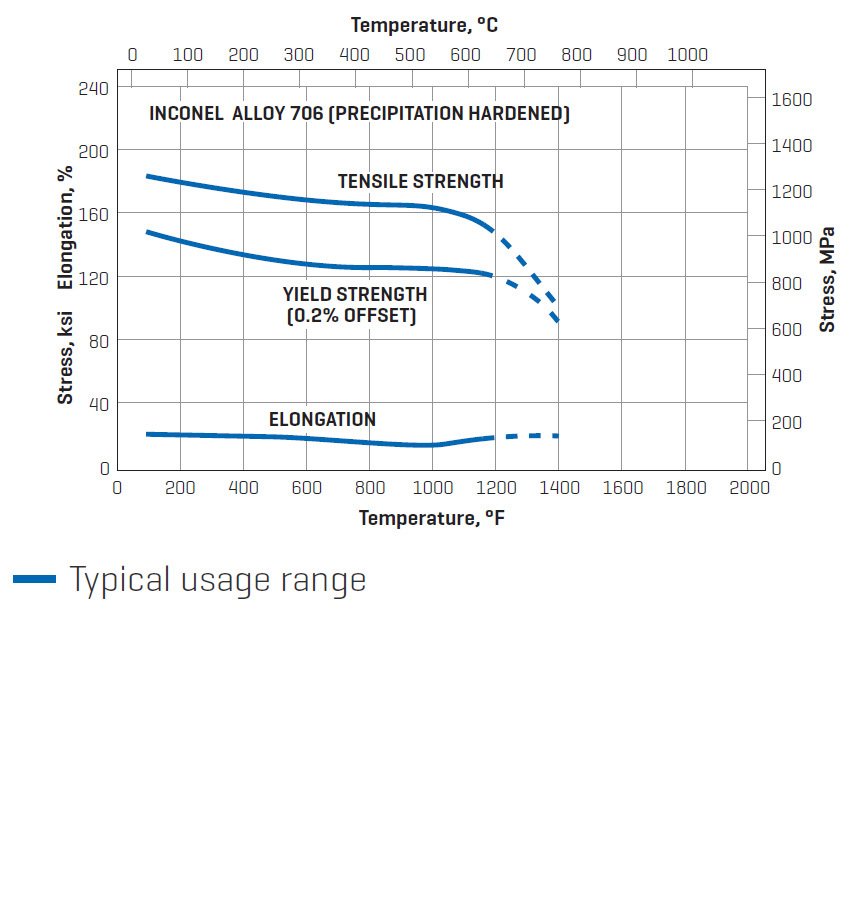

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message