Product Description

A nickel-chromium-aluminum alloy offering the best resistance to metal dusting of any available conventional alloy. Alloy 693 also offers exceptional resistance to oxidation and carburization at temperatures up to 2100°F (1150°C) with excursions to even higher temperatures. The alloy’s ability to resist metal dusting is especially useful in systems used to reform hydrogen and generate synthesis gas for various industries, including gas and liquid fuel production. Alloy 693 is protected by U.S. Patent Number 4,882,125.

STANDARD PRODUCT FORMS

Plate, sheet, strip, bar, seamless tubes and pipes.

MAJOR SPECIFICATIONS

UNS N06693

ASTM B 166, B 167, B 168

ASME SB 166, SB 167, SB 168

ASTM B 166, B 167, B 168

ASME SB 166, SB 167, SB 168

LIMITING CHEMICAL COMPOSITION, %

Ni..... Remaindera

Cr...... 27.0 – 31.0

Fe..............2.5-6.0

Al...............2.5-4.0

Nb.............0.5-2.5

Mn.......... 1.0 max.

Ti............ 1.0 max.

Cu........0.50 max.

Si..........0.50 max.

C...........0.15 max.

S........ 0.015 max.

aElement determined arithmetically by difference.

Cr...... 27.0 – 31.0

Fe..............2.5-6.0

Al...............2.5-4.0

Nb.............0.5-2.5

Mn.......... 1.0 max.

Ti............ 1.0 max.

Cu........0.50 max.

Si..........0.50 max.

C...........0.15 max.

S........ 0.015 max.

aElement determined arithmetically by difference.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.280

g/cm3..........................................................................7.77

Melting Range, °F...................................................2403 – 2493

°C...................................................1317 – 1367

Specific Heat, Btu/lb•°F......................................................0.109

J/kg•°C............................................................ 455

Permeability at 200 Oersted.......................................... <1.005

Electrical ResistivityA, ohm•circ mil/ft............................... 702.7

Thermal ConductivityA, Btu•in/ft2•h•°F................................. 64.3

W/m•°C.................................................9.1

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21–93°C)....................7.22 (13.04)

Young’s ModulusA, 103 psi.................................................... 28.5

GPa........................................................... 197

Shear ModulusA, 103 psi........................................................ 11.0

GPa..................................................................76

Poisson’s RatioA....................................................................... 0.30

ARoom temperature, as aged.

g/cm3..........................................................................7.77

Melting Range, °F...................................................2403 – 2493

°C...................................................1317 – 1367

Specific Heat, Btu/lb•°F......................................................0.109

J/kg•°C............................................................ 455

Permeability at 200 Oersted.......................................... <1.005

Electrical ResistivityA, ohm•circ mil/ft............................... 702.7

Thermal ConductivityA, Btu•in/ft2•h•°F................................. 64.3

W/m•°C.................................................9.1

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21–93°C)....................7.22 (13.04)

Young’s ModulusA, 103 psi.................................................... 28.5

GPa........................................................... 197

Shear ModulusA, 103 psi........................................................ 11.0

GPa..................................................................76

Poisson’s RatioA....................................................................... 0.30

ARoom temperature, as aged.

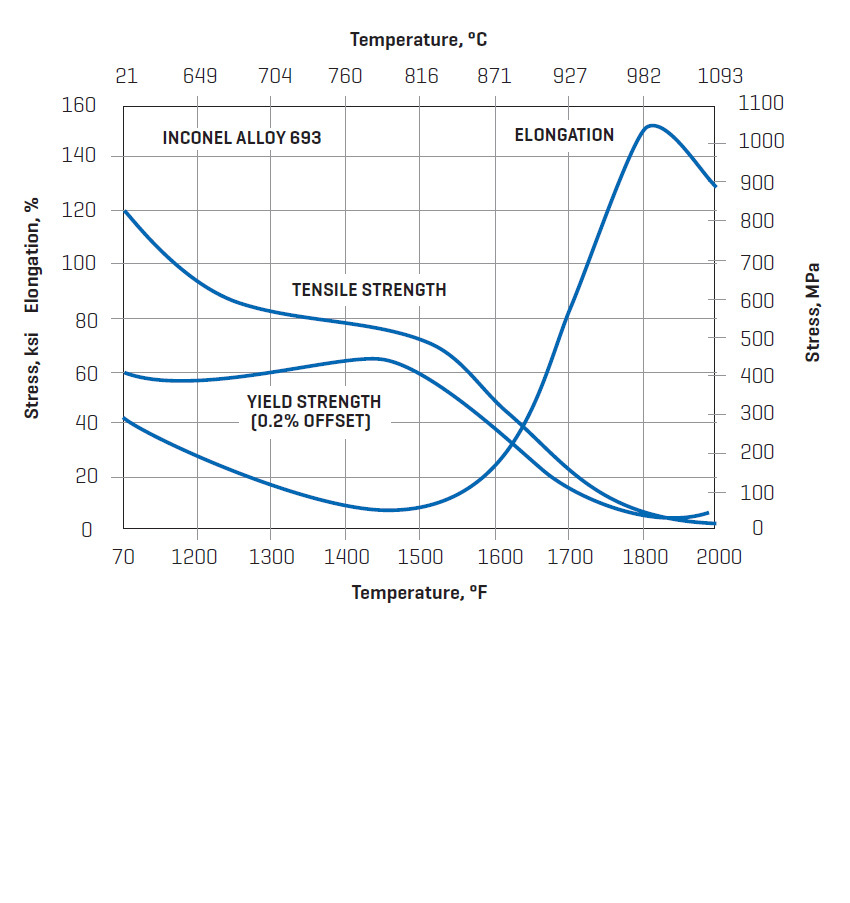

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message