Product Description

A nickel-chromium-molybdenum-niobium alloy that is highly resistant to corrosion and is age hardenable for extremely high strength. The strength of this alloy is developed by heat treatment to achieve high ductility and toughness. The alloy is resistant to hydrogen embrittlement and stress-corrosion cracking. Used for hangers, landing nipples, side pocket mandrels and polished bore receptacles in sour gas service. Also used for high-strength fasteners in marine applications.

STANDARD PRODUCT FORMS

Round bar and wire.

MAJOR SPECIFICATIONS

UNS N07725

ASTM B 805

ASME Code Case 2217

NACE MR-0175/ISO 15156

SMC HA91

ASTM B 805

ASME Code Case 2217

NACE MR-0175/ISO 15156

SMC HA91

LIMITING CHEMICAL COMPOSITION, %

Ni.......55.0 – 59.0

Cr.......19.0 – 22.5

Mo.......... 7.0 – 9.5

Nb....... 2.75 – 4.0

Ti............1.0 – 1.7

Al..........0.35 max.

C...........0.03 max.

Mn........0.35 max.

Si..........0.20 max.

P......... 0.015 max.

S........ 0.010 max.

Fe............ Balance

Cr.......19.0 – 22.5

Mo.......... 7.0 – 9.5

Nb....... 2.75 – 4.0

Ti............1.0 – 1.7

Al..........0.35 max.

C...........0.03 max.

Mn........0.35 max.

Si..........0.20 max.

P......... 0.015 max.

S........ 0.010 max.

Fe............ Balance

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3..........................................................................0.300

g/cm3......................................................................... 8.31

Melting Point, °F......................................................2320 – 2449

°C......................................................1271 – 1343

Permeability at 200 Oersted (15.9 kA/m).................. <1.001

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F......7.22

20 – 100°C, μm/m •°C.......... 13.0

Thermal Conductivity, Btu • in/ft2• h•°F........................... 73.8

W/m•°C........................................... 10.6

Electrical Resistivity, ohm • circ mil/ft.............................. 688

μΩ•m...............................................1.144

g/cm3......................................................................... 8.31

Melting Point, °F......................................................2320 – 2449

°C......................................................1271 – 1343

Permeability at 200 Oersted (15.9 kA/m).................. <1.001

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F......7.22

20 – 100°C, μm/m •°C.......... 13.0

Thermal Conductivity, Btu • in/ft2• h•°F........................... 73.8

W/m•°C........................................... 10.6

Electrical Resistivity, ohm • circ mil/ft.............................. 688

μΩ•m...............................................1.144

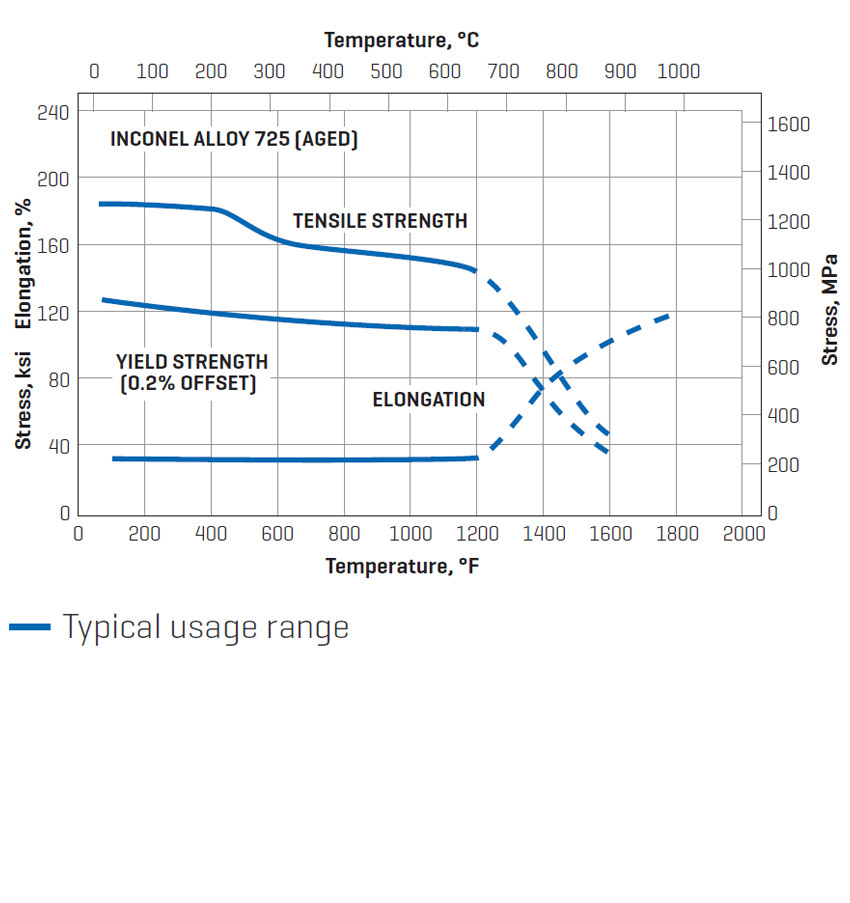

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message