Product Description

A nickel-chromium-cobalt superalloy age hardened by the precipitation of a gamma prime second phase. Alloy 740H exhibits excellent high temperature strength in the age-hardened condition up to 1500°F (815°C). With its high contents of chromium and cobalt, alloy 740H offers excellent resistance to oxidation, carburization and sulfidation at elevated temperatures. Alloy 740H is targeted for use as advanced power production boiler tubes.

STANDARD PRODUCT FORMS

Bar, seamless tubes.

MAJOR SPECIFICATIONS

Contact Special Metals

LIMITING CHEMICAL COMPOSITION, %

Nominal

C..................... 0.03

Ni............. Balance

Cr.................... 25.0

Mo.....................0.5

Co................... 20.0

Al.......................1.0

Ti.......................1.8

Nb.....................2.0

Mn.................. 0.30

Fe......................0.7

Si.......................0.5

C..................... 0.03

Ni............. Balance

Cr.................... 25.0

Mo.....................0.5

Co................... 20.0

Al.......................1.0

Ti.......................1.8

Nb.....................2.0

Mn.................. 0.30

Fe......................0.7

Si.......................0.5

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3..........................................................................0.291

g/cm3......................................................................... 8.05

Melting Point, °F......................................................2350 – 2484

°C......................................................1288 – 1362

Specific Heat, Btu/lb •°F.....................................................0.108

J/kg •°C........................................................... 449

Electrical Resistivity, ohm • circ mil/ft...........................702.7

μΩ•m...............................................1.168

Thermal Conductivity, Btu • in/ft2• h•°F........................... 72.9

W/m•°C........................................... 10.2

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21–93°C)...................6.84 (12.38)

Young’s ModulusA, 103 psi........................................................32

GPa........................................................... 221

Shear’s ModulusA, 103 psi..................................................... 11.5

GPa...............................................................79

Poisson’s RatioA....................................................................... 0.35

Magnetic Permeability..................................................... <1.005

ARoom temperature, as aged.

g/cm3......................................................................... 8.05

Melting Point, °F......................................................2350 – 2484

°C......................................................1288 – 1362

Specific Heat, Btu/lb •°F.....................................................0.108

J/kg •°C........................................................... 449

Electrical Resistivity, ohm • circ mil/ft...........................702.7

μΩ•m...............................................1.168

Thermal Conductivity, Btu • in/ft2• h•°F........................... 72.9

W/m•°C........................................... 10.2

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21–93°C)...................6.84 (12.38)

Young’s ModulusA, 103 psi........................................................32

GPa........................................................... 221

Shear’s ModulusA, 103 psi..................................................... 11.5

GPa...............................................................79

Poisson’s RatioA....................................................................... 0.35

Magnetic Permeability..................................................... <1.005

ARoom temperature, as aged.

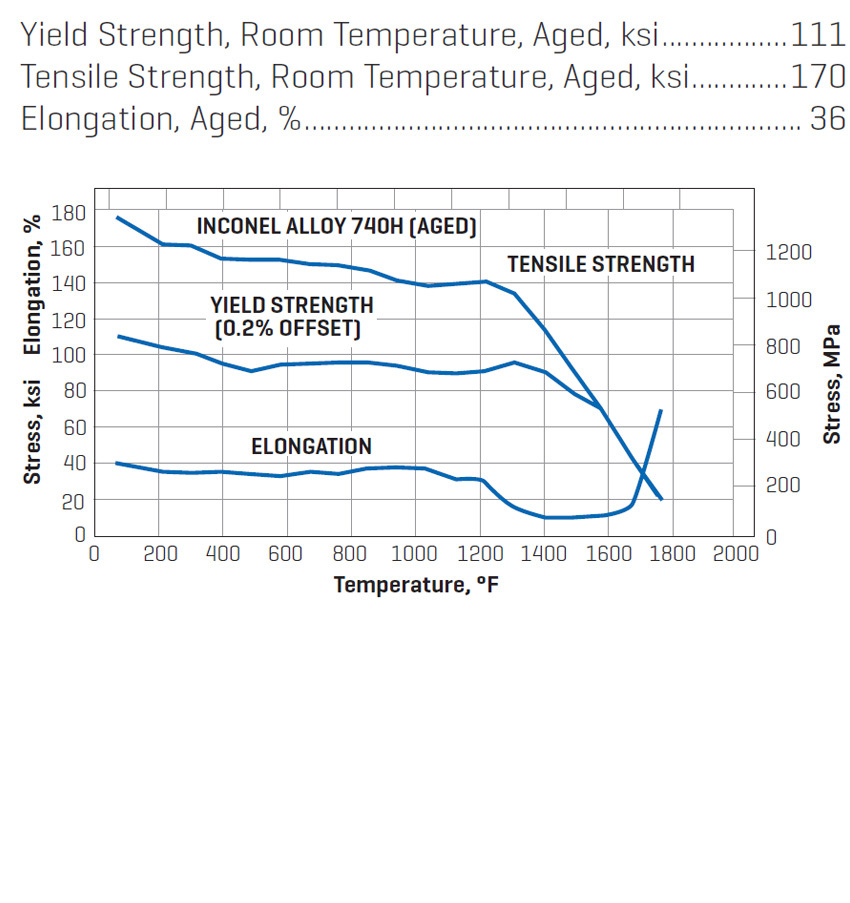

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message