Product Description

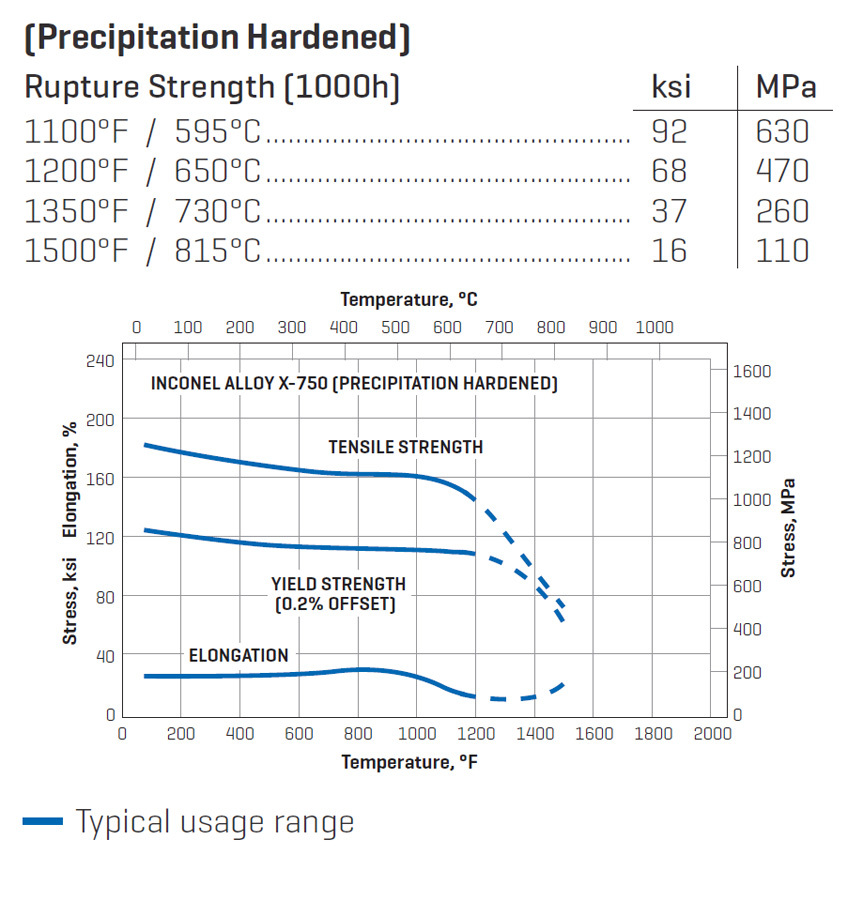

A nickel-chromium alloy similar to INCONEL alloy 600 but made precipitation hardenable by additions of aluminum and titanium. It has good resistance to corrosion and oxidation along with high tensile and creep-rupture properties at temperatures to 1300°F (700°C). Its excellent relaxation resistance is useful for high-temperature springs and bolts. Used in gas turbines, rocket engines, nuclear reactors, pressure vessels, tooling and aircraft structures.

STANDARD PRODUCT FORMS

Sheet, strip, plate, round bar, flat bar, forging stock,

hexagon, wire, tubing and extruded section.

hexagon, wire, tubing and extruded section.

MAJOR SPECIFICATIONS

UNS N07750

BS HR 505

ASTM B 637

ASME SB-637

Werkstoff Nr. 2.4669

NACE MR-0175/ISO 15156

SAE AMS 5542, 5582, 5583,

5598, 5667 – 5671, 5698,

5699, 5747

EN 10269

ISO 6208, 9723 – 9725

BS HR 505

ASTM B 637

ASME SB-637

Werkstoff Nr. 2.4669

NACE MR-0175/ISO 15156

SAE AMS 5542, 5582, 5583,

5598, 5667 – 5671, 5698,

5699, 5747

EN 10269

ISO 6208, 9723 – 9725

LIMITING CHEMICAL COMPOSITION, %

Nia.........70.0 min.

Cr...... 14.0 – 17.0

Fe...........5.0 – 9.0

Ti.......2.25 – 3.75

aPlus Co.

Al.......0.40 – 1.00

Nbb....0.70 – 1.20

C...........0.08 max.

Mn........1.00 max.

bPlus Ta.

Si..........0.50 max.

S...........0.01 max.

Cu........0.50 max.

Coc.......1.00 max.

CIf determined.

Cr...... 14.0 – 17.0

Fe...........5.0 – 9.0

Ti.......2.25 – 3.75

aPlus Co.

Al.......0.40 – 1.00

Nbb....0.70 – 1.20

C...........0.08 max.

Mn........1.00 max.

bPlus Ta.

Si..........0.50 max.

S...........0.01 max.

Cu........0.50 max.

Coc.......1.00 max.

CIf determined.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3..........................................................................0.299

g/cm3......................................................................... 8.28

Melting Point, °F......................................................2540 – 2600

°C......................................................1390 – 1430

Specific Heat, Btu/lb •°F.....................................................0.103

J/kg •°C........................................................... 431

Curie Temperature, °F........................................................... -193

°C.......................................................... -125

Permeability at 200 Oersted (15.9 kA/m).................. 1.0035

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.0

21 – 93°C, μm/m •°C............. 12.6

Thermal Conductivity, Btu • in/ft2• h•°F...............................83

W/m•°C........................................... 12.0

Electrical Resistivity, ohm • circ mil/ft.............................. 731

μΩ•m................................................. 1.22

g/cm3......................................................................... 8.28

Melting Point, °F......................................................2540 – 2600

°C......................................................1390 – 1430

Specific Heat, Btu/lb •°F.....................................................0.103

J/kg •°C........................................................... 431

Curie Temperature, °F........................................................... -193

°C.......................................................... -125

Permeability at 200 Oersted (15.9 kA/m).................. 1.0035

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.0

21 – 93°C, μm/m •°C............. 12.6

Thermal Conductivity, Btu • in/ft2• h•°F...............................83

W/m•°C........................................... 12.0

Electrical Resistivity, ohm • circ mil/ft.............................. 731

μΩ•m................................................. 1.22

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message