Product Description

A nickel-chromium alloy similar to INCONEL alloy X-750 but with increased aluminum content for greater precipitation hardening. This alloy was designed for use as exhaust valves in internal-combustion engines. In that application, the alloy offers high strength at operating temperatures, high hot hardness for wear resistance, and corrosion resistance in hot exhaust gases containing lead oxide, sulfur, bromine and chlorine.

STANDARD PRODUCT FORMS

Round bar.

MAJOR SPECIFICATIONS

UNS N07751

LIMITING CHEMICAL COMPOSITION, %

Limiting

Nia.........70.0 min.

Cr...... 14.0 – 17.0

Fe...........5.0 – 9.0

aPlus Co. bPlus Ta.

Ti.............2.0 – 2.6

Al.............0.9 – 1.5

Nbb..........0.7 – 1.2

C...........0.10 max.

Mn.......... 1.0 max.

Si............ 0.5 max.

S...........0.01 max.

Cu........0.05 max.

Nia.........70.0 min.

Cr...... 14.0 – 17.0

Fe...........5.0 – 9.0

aPlus Co. bPlus Ta.

Ti.............2.0 – 2.6

Al.............0.9 – 1.5

Nbb..........0.7 – 1.2

C...........0.10 max.

Mn.......... 1.0 max.

Si............ 0.5 max.

S...........0.01 max.

Cu........0.05 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3..........................................................................0.299

g/cm3......................................................................... 8.28

Melting Point, °F......................................................2540 – 2600

°C......................................................1390 – 1430

Specific Heat, Btu/lb •°F.....................................................0.103

J/kg •°C........................................................... 431

Curie Temperature, °F........................................................... -193

°C.......................................................... -125

Permeability at 200 Oersted (15.9 kA/m).................. 1.0035

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.0

21 – 93°C, μm/m •°C............. 12.6

Thermal Conductivity, Btu • in/ft2• h•°F...............................83

W/m•°C........................................... 12.0

Electrical Resistivity, ohm • circ mil/ft.............................. 731

μΩ•m................................................. 1.22

g/cm3......................................................................... 8.28

Melting Point, °F......................................................2540 – 2600

°C......................................................1390 – 1430

Specific Heat, Btu/lb •°F.....................................................0.103

J/kg •°C........................................................... 431

Curie Temperature, °F........................................................... -193

°C.......................................................... -125

Permeability at 200 Oersted (15.9 kA/m).................. 1.0035

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.0

21 – 93°C, μm/m •°C............. 12.6

Thermal Conductivity, Btu • in/ft2• h•°F...............................83

W/m•°C........................................... 12.0

Electrical Resistivity, ohm • circ mil/ft.............................. 731

μΩ•m................................................. 1.22

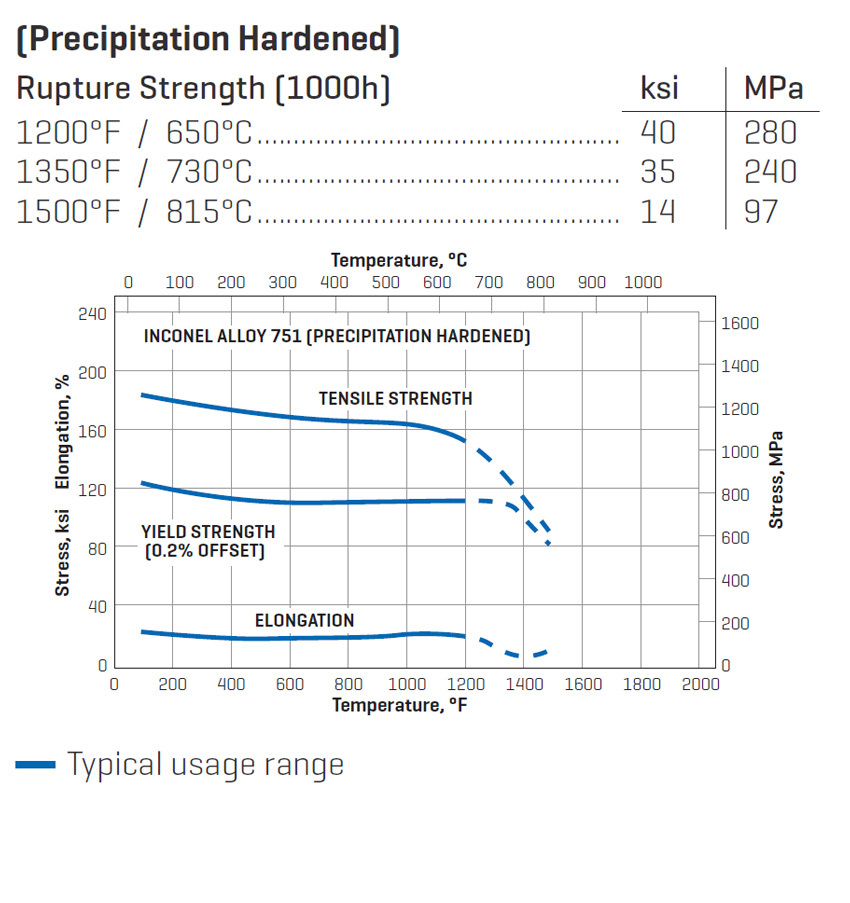

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message