Product Description

A nickel-chromium alloy with good strength and excellent resistance to oxidation and carburization in high-temperature atmospheres. It also resists corrosion by many aqueous environments. The alloy maintains a stable, austenitic structure during prolonged exposure to high temperatures. Used for process piping, heat exchangers, carburizing equipment, heating-element sheathing and nuclear steam-generator tubing.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon and wire.

stock, hexagon and wire.

MAJOR SPECIFICATIONS

UNS N08800

BS 3072 – 3076 (NA15)

ASTM B 163, A 240, B 366,

B 407 – B 409, A 480, B 514,

B 515, B 564, B 751,

B 775, B 829

DIN 470

Werkstoff Nr. 1.4876

VdTÜV 412

ASME SB-163, SA-240,

SB-366, SB-407 – SB-409,

SA-480, SB-514, SB-515,

SB-564, SB-751, SB-775,

SB-829

ASME Code Cases 1325,

1949, 2339, N-20

SAE AMS 5766, 5871

NACE MR-0175/ISO 15156

ISO 9723 – 9725, 6207, 6208

BS 3072 – 3076 (NA15)

ASTM B 163, A 240, B 366,

B 407 – B 409, A 480, B 514,

B 515, B 564, B 751,

B 775, B 829

DIN 470

Werkstoff Nr. 1.4876

VdTÜV 412

ASME SB-163, SA-240,

SB-366, SB-407 – SB-409,

SA-480, SB-514, SB-515,

SB-564, SB-751, SB-775,

SB-829

ASME Code Cases 1325,

1949, 2339, N-20

SAE AMS 5766, 5871

NACE MR-0175/ISO 15156

ISO 9723 – 9725, 6207, 6208

LIMITING CHEMICAL COMPOSITION, %

Ni.......30.0 – 35.0

Fe..........39.5 min.

Cr......19.0 – 23.0

C...........0.10 max.

Mn........1.50 max.

S........ 0.015 max.

Si............ 1.0 max.

Cu........0.75 max.

Al.......0.15 – 0.60

Ti.......0.15 – 0.60

Fe..........39.5 min.

Cr......19.0 – 23.0

C...........0.10 max.

Mn........1.50 max.

S........ 0.015 max.

Si............ 1.0 max.

Cu........0.75 max.

Al.......0.15 – 0.60

Ti.......0.15 – 0.60

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3 (g/cm3)............................................ 0.287 (7.94)

Melting Range, °F (°C)..............2475 – 2525 (1357 – 1385)

Specific Heat, Btu/lb•°F (J/kg•°C)......................... 0.11 (460)

Curie Temperature, °F (°C)....................................-175 (-115)

Permeability at 200 Oersted (15.9 kA/m).....................1.014

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (20-100°C)...................... 7.9 (14.4)

Thermal ConductivityA, Btu•in/ft2•h•°F (W/m•°C)........80 (11.5)

Electrical ResistivityA, ohm•circ mil/ft (μΩ•m)....... 595 (0.989)

Melting Range, °F (°C)..............2475 – 2525 (1357 – 1385)

Specific Heat, Btu/lb•°F (J/kg•°C)......................... 0.11 (460)

Curie Temperature, °F (°C)....................................-175 (-115)

Permeability at 200 Oersted (15.9 kA/m).....................1.014

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (20-100°C)...................... 7.9 (14.4)

Thermal ConductivityA, Btu•in/ft2•h•°F (W/m•°C)........80 (11.5)

Electrical ResistivityA, ohm•circ mil/ft (μΩ•m)....... 595 (0.989)

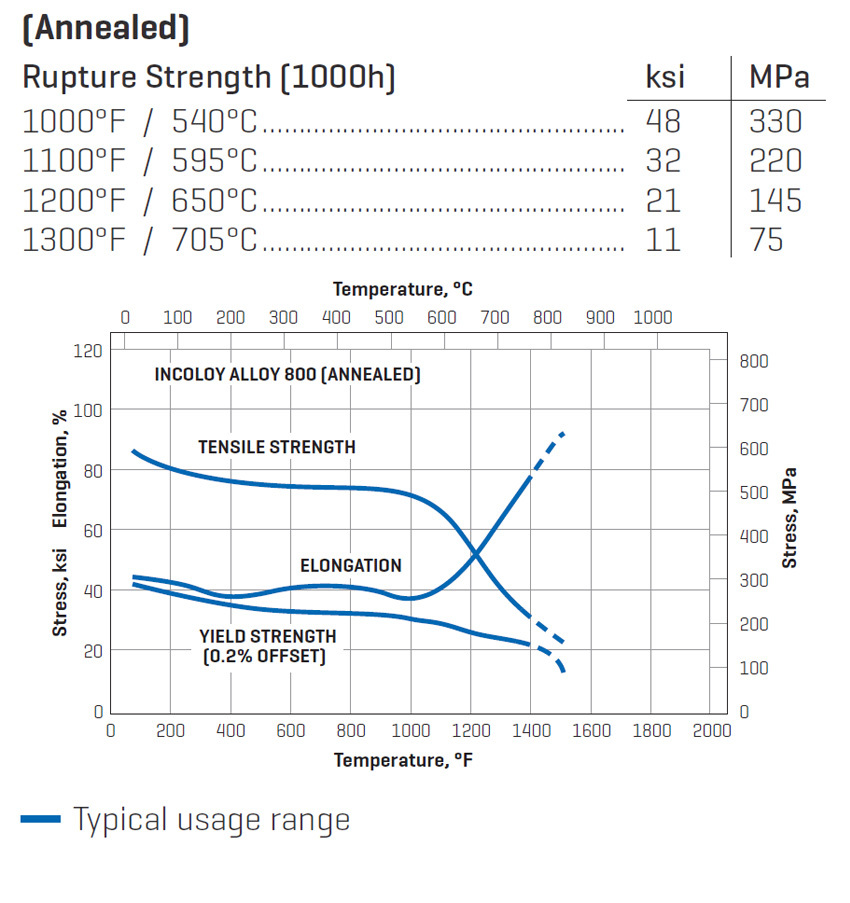

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message