Product Description

Nickel-iron-chromium alloys that have the same basic composition as INCOLOY alloy 800 but with significantly higher creep-rupture strength. The higher strength results from close control of the carbon, aluminum and titanium contents in conjunction with a hightemperature anneal. Used in chemical and petrochemical processing, power plants for super-heater and reheater tubing, industrial furnaces and heat-treating equipment.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon and wire.

stock, hexagon and wire.

MAJOR SPECIFICATIONS

UNS N08810, N08811

BS 3072, 3073, 3074, 3075,

3076 (NA15)

ASTM A 240, A 480, B 163,

B 366, B 407 – 409,

B 514, B 515, B 564,

B 751, B 775, B 829

ASME SA-240, SA-480,

SB-163, SB-366,

SB-407 – SB-409, SB-514,

SB-515, SB-564, SB-751,

SB-775, SB-829

ASME Code Cases 1325,

1949, 1983, 2339,

N-201, N-254

DIN 17459, 17460

Werkstoff Nr. 1.4876, 1.4958,

1.4959

VdTÜV 412, 434

EN 10028-7, 10095

ISO 4955A, 6207, 6208,

9723, 9725

BS 3072, 3073, 3074, 3075,

3076 (NA15)

ASTM A 240, A 480, B 163,

B 366, B 407 – 409,

B 514, B 515, B 564,

B 751, B 775, B 829

ASME SA-240, SA-480,

SB-163, SB-366,

SB-407 – SB-409, SB-514,

SB-515, SB-564, SB-751,

SB-775, SB-829

ASME Code Cases 1325,

1949, 1983, 2339,

N-201, N-254

DIN 17459, 17460

Werkstoff Nr. 1.4876, 1.4958,

1.4959

VdTÜV 412, 434

EN 10028-7, 10095

ISO 4955A, 6207, 6208,

9723, 9725

LIMITING CHEMICAL COMPOSITION, %

800H

Ni........30.0–35.0

Fe.........39.5 min.

Cr.......19.0–23.0

C.........0.05–0.10

Al........0.15–0.60

Ti............0.15–0.60

Al+Ti......0.30–1.20

800HT

Ni........30.0–35.0

Fe.........39.5 min.

Cr.......19.0–23.0

C.........0.06–0.10

Al........0.25–0.60

Ti............0.25–0.60

Al+Ti......0.85–1.20

* By special agreement, this product can be supplied with

aluminum + titanium limited to 0.4 – 0.7%.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3 (g/cm3)............................................ 0.287 (7.94)

Melting Range, °F (°C)..............2475 – 2525 (1357 – 1385)

Specific Heat, Btu/lb•°F (J/kg•°C)......................... 0.11 (460)

Curie Temperature, °F (°C)....................................-175 (-115)

Permeability at 200 Oersted (15.9 kA/m).....................1.014

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (20-100°C)...................... 7.9 (14.4)

Thermal ConductivityA, Btu•in/ft2•h•°F (W/m•°C)........80 (11.5)

Electrical ResistivityA, ohm•circ mil/ft (μΩ•m)....... 595 (0.989)

Melting Range, °F (°C)..............2475 – 2525 (1357 – 1385)

Specific Heat, Btu/lb•°F (J/kg•°C)......................... 0.11 (460)

Curie Temperature, °F (°C)....................................-175 (-115)

Permeability at 200 Oersted (15.9 kA/m).....................1.014

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (20-100°C)...................... 7.9 (14.4)

Thermal ConductivityA, Btu•in/ft2•h•°F (W/m•°C)........80 (11.5)

Electrical ResistivityA, ohm•circ mil/ft (μΩ•m)....... 595 (0.989)

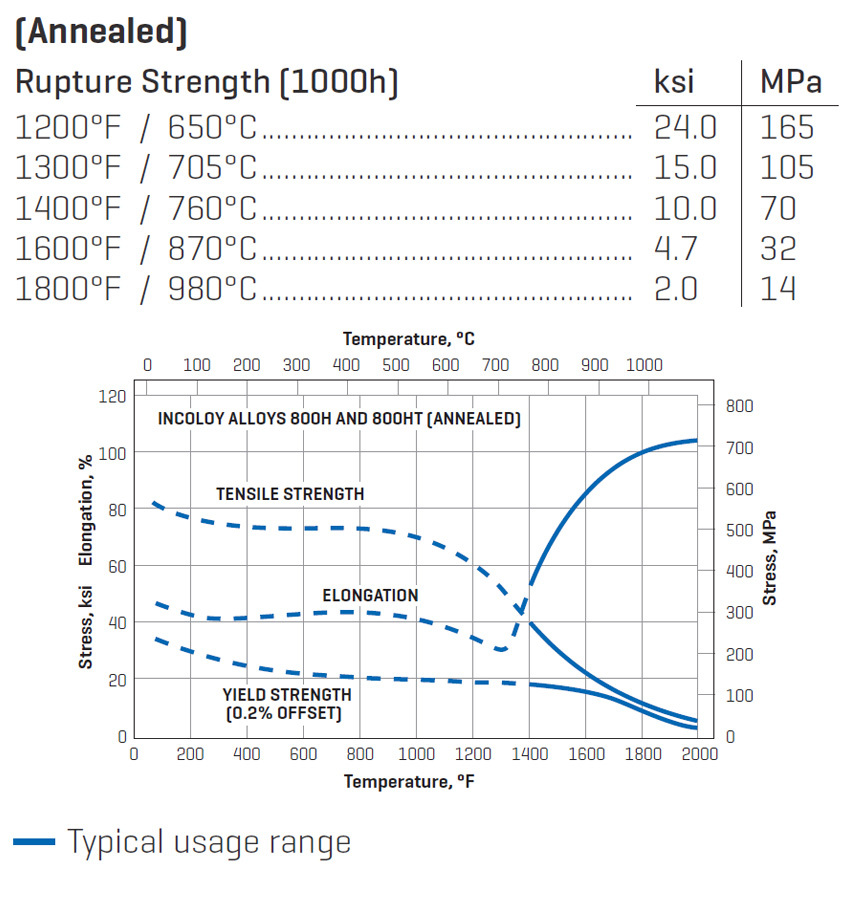

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message