Product Description

Designed for use in petrochemical, chemical and thermal processing applications, the alloy provides an exceptional level of high-temperature corrosion-resistance in oxidation, sulfidation, carburization and nitridation environments. In addition to thermal stability characteristics required to prevent thermal distortion and embrittlement, it exhibits excellent stress-rupture strengths. These characteristics, along with a high resistance to carburization and cyclic oxidation, make this alloy the material of choice for many severe applications including ID-finned pyrolysis tubing in high-severity ethylene furnaces.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, ID finned tube and wire.

stock, ID finned tube and wire.

MAJOR SPECIFICATIONS

UNS S35045

ASTM A 182, A 213, A 240, A 249, A 480

ASME Code Case 2304

ASME SA 182, SA 213, SA 240, SA 249, SA 480

ASTM A 182, A 213, A 240, A 249, A 480

ASME Code Case 2304

ASME SA 182, SA 213, SA 240, SA 249, SA 480

LIMITING CHEMICAL COMPOSITION, %

Ni....... 32.0 – 37.0

Fe.......Remainder

Cr......25.0 – 29.0

C........0.06 – 0.10

Mn........1.50 max.

S........ 0.015 max.

Si............ 1.0 max.

Cu........0.75 max.

Al.......0.15 – 0.60

Ti.......0.15 – 0.60

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3 (g/cm3)............................................ 0.284 (7.86)

Melting Range, °F (°C)..............2490 – 2555 (1365 – 1400)

Specific Heat, Btu/lb•°F (J/kg•°C).......................0.114 (479)

Permeability at 200 Oersted (15.9 kA/m).....................1.001

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C)...................... 8.31 (15.0)

70-800°F (21-427°C)................... 9.14 (16.5)

70-1200°F (21-649°C)..................9.48 (17.1)

Thermal ConductivityA, Btu•in/ft2•h•°F (W/m•°C)........78 (11.3)

Electrical ResistivityA, ohm•circ mil/ft (μΩ•m)..........618 (1.03)

Young’s ModulusA, 106 psi (GPa)............................ 28.3 (195)

Shear’s ModulusA, 106 psi (GPa)............................ 10.7 (73.8)

Poisson’s RatioA....................................................................... 0.32

ARoom temperature, as solution annealed.

Melting Range, °F (°C)..............2490 – 2555 (1365 – 1400)

Specific Heat, Btu/lb•°F (J/kg•°C).......................0.114 (479)

Permeability at 200 Oersted (15.9 kA/m).....................1.001

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C)...................... 8.31 (15.0)

70-800°F (21-427°C)................... 9.14 (16.5)

70-1200°F (21-649°C)..................9.48 (17.1)

Thermal ConductivityA, Btu•in/ft2•h•°F (W/m•°C)........78 (11.3)

Electrical ResistivityA, ohm•circ mil/ft (μΩ•m)..........618 (1.03)

Young’s ModulusA, 106 psi (GPa)............................ 28.3 (195)

Shear’s ModulusA, 106 psi (GPa)............................ 10.7 (73.8)

Poisson’s RatioA....................................................................... 0.32

ARoom temperature, as solution annealed.

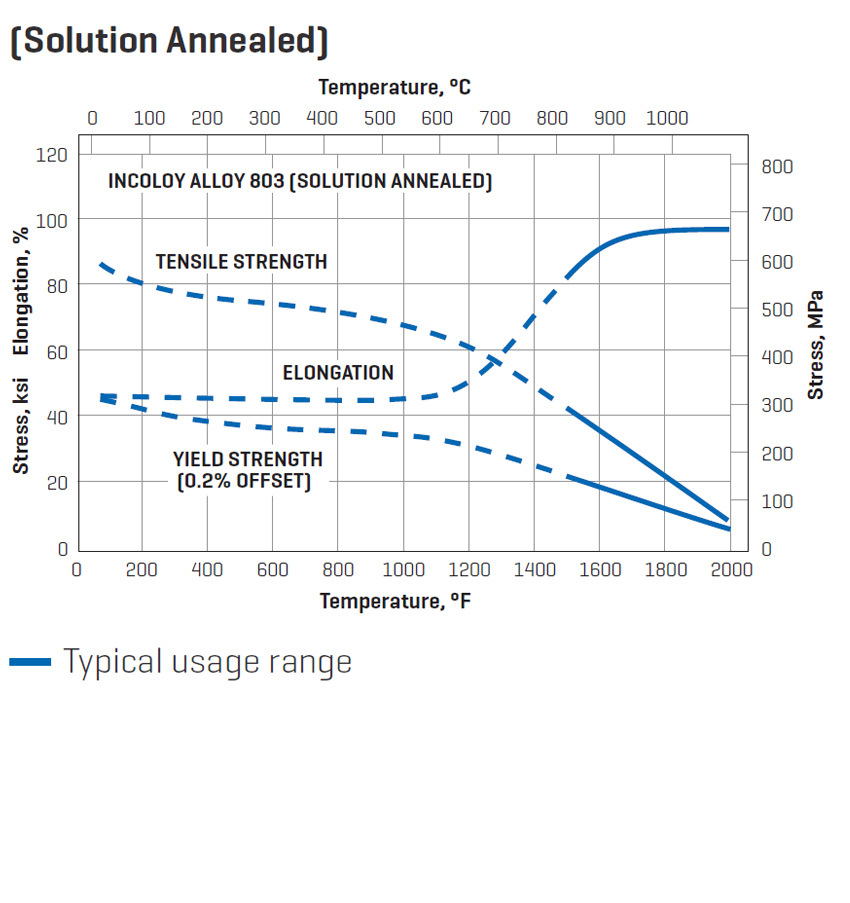

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message