Product Description

A nickel-iron-chromium alloy with additions of molybdenum and copper. It has excellent resistance to both reducing and oxidizing acids, stress-corrosion cracking and localized attack such as pitting and crevice corrosion. The alloy is especially resistant to sulfuric and phosphoric acids. Used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production and pickling equipment.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon and wire.

stock, hexagon and wire.

MAJOR SPECIFICATIONS

UNS N08825

BS 3072 – BS 3074, 3076 (NA16)

ASTM B 163, B 366,

B 423 – B 425, B 564, B 704,

B 705, B 751, B 775, B 829

Werkstoff Nr. 2.4858

VdTÜV 432

NACE MR-0175/ISO 15156

ASME SB-163, SB-366,

SB-423 – SB-425, SB-564,

SB-704, SB-705, SB-751,

SB-775, SB-829

ASME Code Cases 1936, N-572

DIN 17744, 17750 – 17754

ISO 6207, 6208, 9723 – 9725

BS 3072 – BS 3074, 3076 (NA16)

ASTM B 163, B 366,

B 423 – B 425, B 564, B 704,

B 705, B 751, B 775, B 829

Werkstoff Nr. 2.4858

VdTÜV 432

NACE MR-0175/ISO 15156

ASME SB-163, SB-366,

SB-423 – SB-425, SB-564,

SB-704, SB-705, SB-751,

SB-775, SB-829

ASME Code Cases 1936, N-572

DIN 17744, 17750 – 17754

ISO 6207, 6208, 9723 – 9725

LIMITING CHEMICAL COMPOSITION, %

Ni.......38.0 – 46.0

Fe..........22.0 min.

Cr......19.5 – 23.5

Mo..........2.5 – 3.5

Cu..........1.5 – 3.0

Ti............0.6 – 1.2

C...........0.05 max.

Mn.......... 1.0 max.

S...........0.03 max.

Si............ 0.5 max.

Al............ 0.2 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.294

g/cm3......................................................................... 8.14

Melting Range, °F...................................................2500 – 2550

°C...................................................1370 – 1400

Specific Heat, Btu/lb•°F......................................................0.105

J/kg•°C............................................................ 440

Curie Temperature, °F.........................................................<-320

°C........................................................<-196

Permeability at 200 Oersted (15.9 kA/m).....................1.005

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C)......................... 7.8 (14.0)

Thermal ConductivityA, Btu•in/ft2•h•°F.................................... 76.8

W/m•°C.................................................. 11.1

Electrical ResistivityA, ohm•circ mil/ft.....................................678

μΩ•m.....................................................1.13

g/cm3......................................................................... 8.14

Melting Range, °F...................................................2500 – 2550

°C...................................................1370 – 1400

Specific Heat, Btu/lb•°F......................................................0.105

J/kg•°C............................................................ 440

Curie Temperature, °F.........................................................<-320

°C........................................................<-196

Permeability at 200 Oersted (15.9 kA/m).....................1.005

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C)......................... 7.8 (14.0)

Thermal ConductivityA, Btu•in/ft2•h•°F.................................... 76.8

W/m•°C.................................................. 11.1

Electrical ResistivityA, ohm•circ mil/ft.....................................678

μΩ•m.....................................................1.13

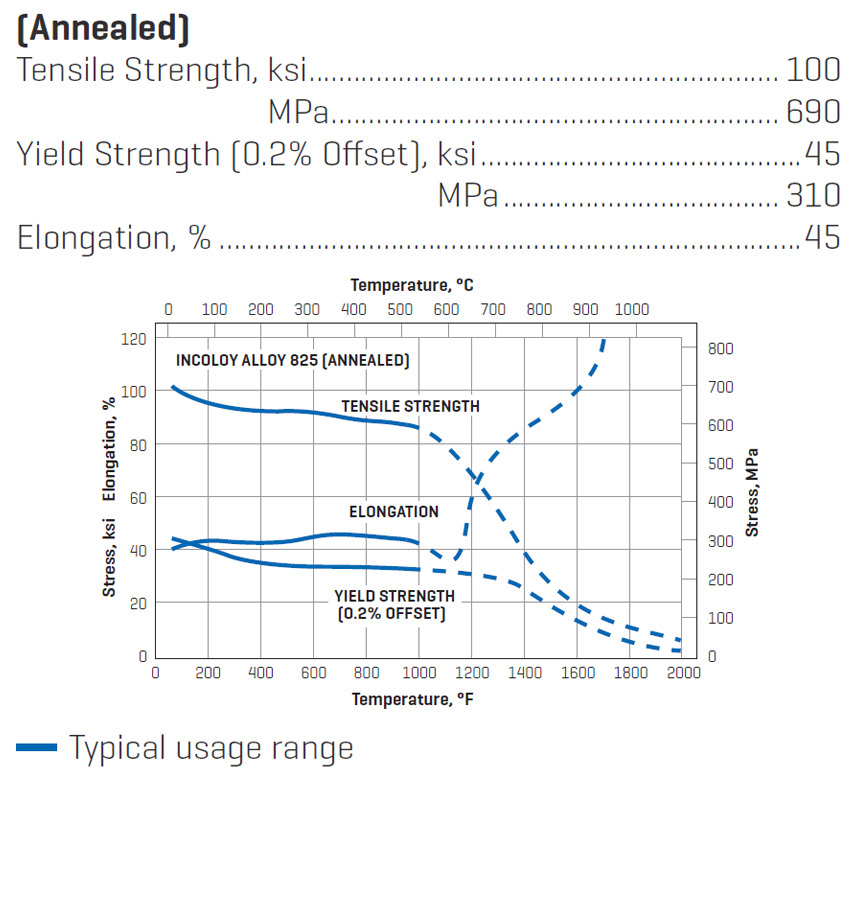

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message