Product Description

A new high-performance and cost-effective alloy specifically developed for automotive exhaust system flexible couplings. Potentially useful for exhaust gas recirculation tubes and other fabricated exhaust system components.

STANDARD PRODUCT FORMS

Sheet and strip.

MAJOR SPECIFICATIONS

UNS S35135

ASTM A 240, A 480

ASTM A 240, A 480

LIMITING CHEMICAL COMPOSITION, %

Ni.......30.0 – 38.0

Fe.......Remainder

Cr......20.0 – 25.0

Mo..........4.0 – 4.8

C...........0.08 max.

Si............0.6 – 1.0

Mn.................. 0.01

S........ 0.015 max.

Ti............0.4 – 1.0

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.290

g/cm3......................................................................... 8.02

Melting Range, °F...................................................2467 – 2539

°C...................................................1353 – 1393

Permeability at 200 Oersted (15.9 kA/m).....................1.004

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C)...................... 8.15 (14.7)

70-800°F (21-427°C)................... 8.90 (15.9)

70-1200°F (21-649°C)................. 9.21 (16.4)

Thermal ConductivityA, Btu • in/ft2•h•°F......................... 78.1

W/m •°C......................................... 11.3

Electrical ResistivityA, ohm •circ mil/ft.............................. 628

μΩ•m............................................... 1.04

Young's ModulusA, 106 psi.................................................... 28.3

GPa........................................................... 195

ARoom temperature, as annealed.

g/cm3......................................................................... 8.02

Melting Range, °F...................................................2467 – 2539

°C...................................................1353 – 1393

Permeability at 200 Oersted (15.9 kA/m).....................1.004

Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C)

70-200°F (21-93°C)...................... 8.15 (14.7)

70-800°F (21-427°C)................... 8.90 (15.9)

70-1200°F (21-649°C)................. 9.21 (16.4)

Thermal ConductivityA, Btu • in/ft2•h•°F......................... 78.1

W/m •°C......................................... 11.3

Electrical ResistivityA, ohm •circ mil/ft.............................. 628

μΩ•m............................................... 1.04

Young's ModulusA, 106 psi.................................................... 28.3

GPa........................................................... 195

ARoom temperature, as annealed.

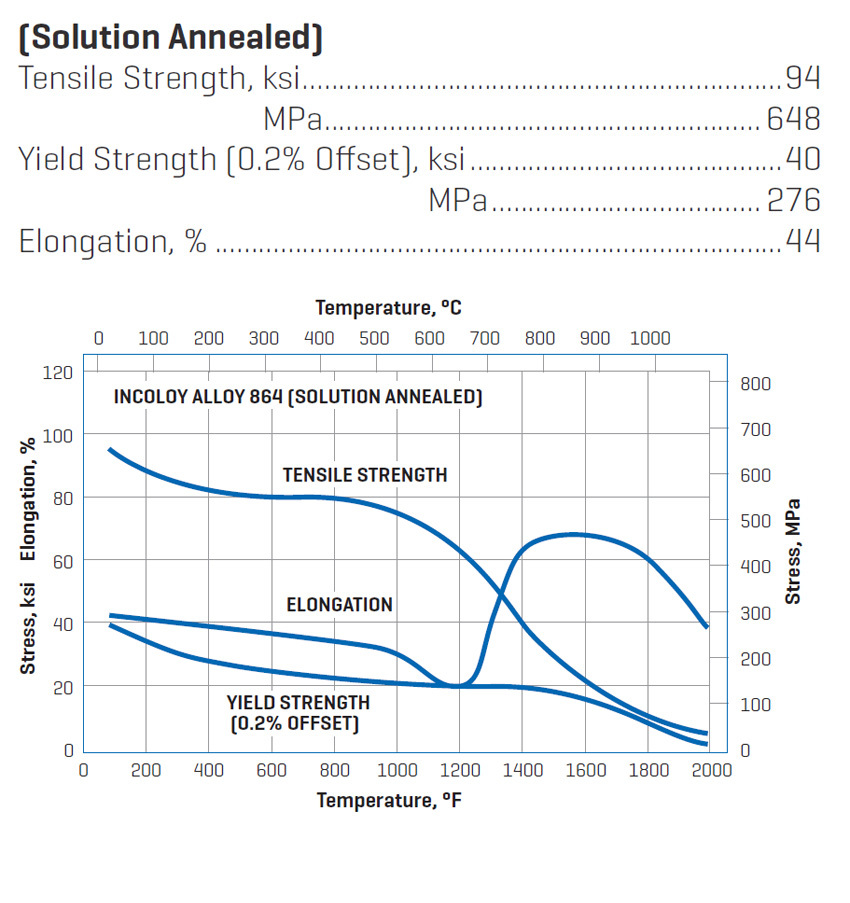

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message

SHANGHAI KANGSHENG AVIATION MATERIALS TECHNOLOGY CO., LTD.

Address: No. 5999, Huyi Road, Waigang Town, Jiading District, Shanghai

Tel:13641813331

Technical support:13671903676

Emial:ksalloy@ksalloy.com

Copyright: 2022 Shanghai Kangsheng Aviation Materials Technology Co., Ltd.

Powered By:www.300.cn SEO