Product Description

A nickel-iron-cobalt alloy with additions of niobium and titanium for precipitation hardening. It has the low coefficient of expansion and high strength of INCOLOY alloy 903 but with improved notch-rupture properties at elevated temperatures. Used for components of gas turbines including seals, shafts and casings.

STANDARD PRODUCT FORMS

Round bar and forging stock.

MAJOR SPECIFICATIONS

UNS N19907

LIMITING CHEMICAL COMPOSITION, %

Ni.......35.0 – 40.0

Fe.......Remainder

Cu.....12.0 – 16.0

Nb..........4.3 – 5.2

Ti............1.3 – 1.8

Al............ 0.2 max.

Si.......0.07 – 0.35

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.301

g/cm3......................................................................... 8.33

Melting Range, °F....................................................2440 – 2550

°C....................................................1335 – 1400

Specific Heat, Btu/lb•°F.....................................................0.103

J/kg•°C............................................................ 431

Curie Temperature, °F................................................750 – 850

°C................................................400 – 455

Coefficient of Expansion, 77 – 800°F, 10-6 in/in •°F........4.3

25 – 427°C, μm/m •°C............. 7.7

Thermal Conductivity, Btu • in/ft2•h•°F............................ 103

W/m • °C.......................................... 14.8

Electrical Resistivity, ohm •circ mil/ft................................ 419

μΩ•m...............................................0.697

g/cm3......................................................................... 8.33

Melting Range, °F....................................................2440 – 2550

°C....................................................1335 – 1400

Specific Heat, Btu/lb•°F.....................................................0.103

J/kg•°C............................................................ 431

Curie Temperature, °F................................................750 – 850

°C................................................400 – 455

Coefficient of Expansion, 77 – 800°F, 10-6 in/in •°F........4.3

25 – 427°C, μm/m •°C............. 7.7

Thermal Conductivity, Btu • in/ft2•h•°F............................ 103

W/m • °C.......................................... 14.8

Electrical Resistivity, ohm •circ mil/ft................................ 419

μΩ•m...............................................0.697

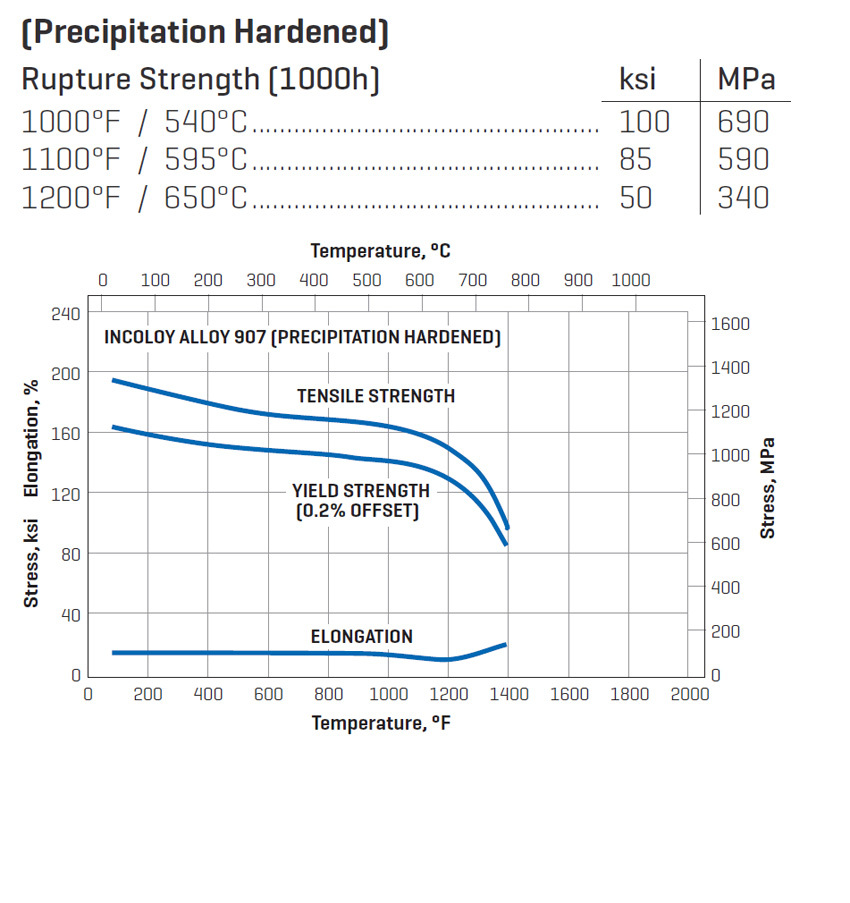

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message

SHANGHAI KANGSHENG AVIATION MATERIALS TECHNOLOGY CO., LTD.

Address: No. 5999, Huyi Road, Waigang Town, Jiading District, Shanghai

Tel:13641813331

Technical support:13671903676

Emial:ksalloy@ksalloy.com

Copyright: 2022 Shanghai Kangsheng Aviation Materials Technology Co., Ltd.

Powered By:www.300.cn SEO