Product Description

A nickel-iron-cobalt alloy with a silicon addition containing niobium and titanium for precipitation hardening. It is similar to INCOLOY alloys 903 and 907 because it has low thermal expansion and high strength. However, the silicon addition results in improved notch-rupture and tensile properties achieved with less-restrictive processing and significantly shorter heat treatments. Used for gas-turbine casings, shrouds, vanes and shafts.

STANDARD PRODUCT FORMS

Round bar, forging stock and hot-rolled profile.

MAJOR SPECIFICATIONS

UNS N19909

SAE AMS 5884, 5892, 5893

SAE AMS 5884, 5892, 5893

LIMITING CHEMICAL COMPOSITION, %

Ni.......35.0 – 40.0

Fe.......Remainder

Co......12.0 – 16.0

Nb..........4.3 – 5.2

Ti............1.3 – 1.8

Si.......0.25 – 0.50

Al..........0.15 max.

C...........0.06 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.296

g/cm3......................................................................... 8.19

Melting Range, °F...................................................2540 – 2610

°C...................................................1395 – 1430

Specific Heat, Btu/lb•°F.....................................................0.102

J/kg•°C............................................................ 427

Curie Temperature, °F................................................750 – 850

°C................................................400 – 455

Coefficient of Expansion, 77 – 800°F, 10-6 in/in •°F........4.3

25 – 427°C, μm/m •°C............. 7.7

Thermal Conductivity, Btu • in/ft2•h•°F............................ 103

W/m •°C........................................... 14.8

Electrical Resistivity, ohm •circ mil/ft................................ 438

μΩ•m...............................................0.728

g/cm3......................................................................... 8.19

Melting Range, °F...................................................2540 – 2610

°C...................................................1395 – 1430

Specific Heat, Btu/lb•°F.....................................................0.102

J/kg•°C............................................................ 427

Curie Temperature, °F................................................750 – 850

°C................................................400 – 455

Coefficient of Expansion, 77 – 800°F, 10-6 in/in •°F........4.3

25 – 427°C, μm/m •°C............. 7.7

Thermal Conductivity, Btu • in/ft2•h•°F............................ 103

W/m •°C........................................... 14.8

Electrical Resistivity, ohm •circ mil/ft................................ 438

μΩ•m...............................................0.728

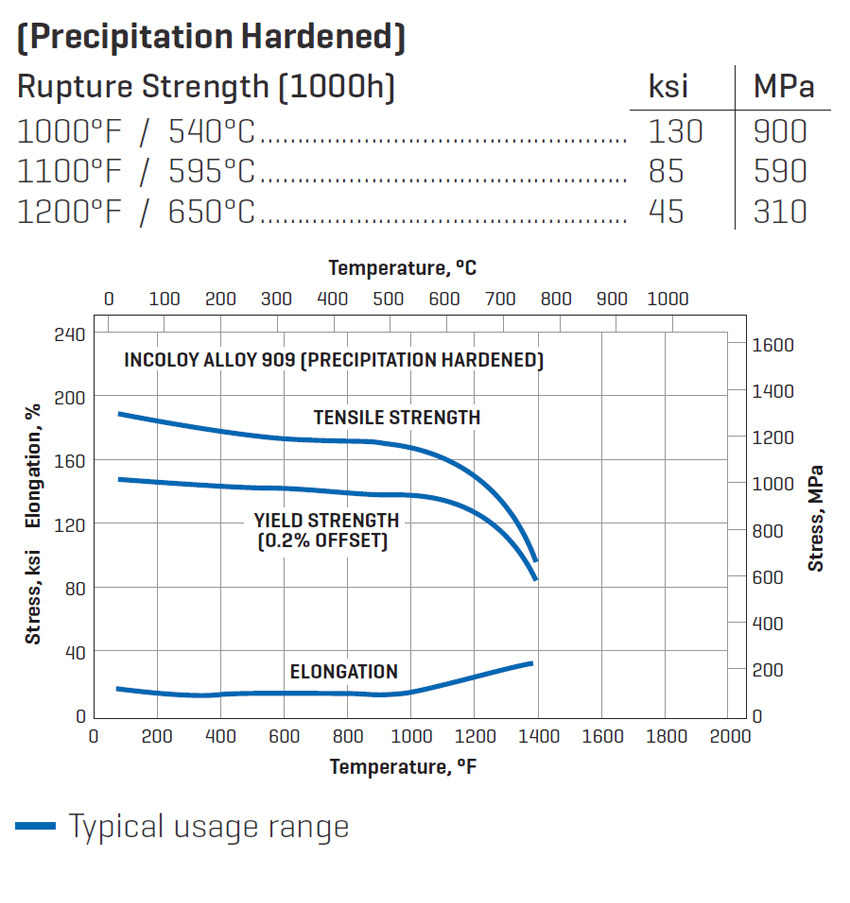

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message