Product Description

A precipitation-hardenable nickel-copper alloy

that combines the corrosion resistance of

MONEL alloy 400 with greater strength and

hardness. It also has low permeability and is

nonmagnetic to temperatures as low as -150°F

(-101°C). Used for pump shafts, oil-well tools and

instruments, doctor blades and scrapers, springs,

valve trim, fasteners and marine propeller shafts.

that combines the corrosion resistance of

MONEL alloy 400 with greater strength and

hardness. It also has low permeability and is

nonmagnetic to temperatures as low as -150°F

(-101°C). Used for pump shafts, oil-well tools and

instruments, doctor blades and scrapers, springs,

valve trim, fasteners and marine propeller shafts.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon and wire.

stock, hexagon and wire.

MAJOR SPECIFICATIONS

UNS N05500

BS 3072 – 3076 (NA18)

ASTM B 865

SAE AMS 4676

DIN 17743, 17752 –17754

Werkstoff Nr. 2.4375

QQ-N 286

NACE MR-0175/ISO 15156

ISO 6208, 9723 – 9725

ASME Code Case 1192

BS 3072 – 3076 (NA18)

ASTM B 865

SAE AMS 4676

DIN 17743, 17752 –17754

Werkstoff Nr. 2.4375

QQ-N 286

NACE MR-0175/ISO 15156

ISO 6208, 9723 – 9725

ASME Code Case 1192

LIMITING CHEMICAL COMPOSITION, %

Nia.........63.0 min.

Cu..... 27.0 – 33.0

Al.......2.30 – 3.15

aPlus Co.

Ti.......0.35 – 0.85

Fe........... 2.0 max.

C...........0.25 max.

Mn.......... 1.5 max.

S...........0.01 max.

Si............ 0.5 max.

Cu..... 27.0 – 33.0

Al.......2.30 – 3.15

aPlus Co.

Ti.......0.35 – 0.85

Fe........... 2.0 max.

C...........0.25 max.

Mn.......... 1.5 max.

S...........0.01 max.

Si............ 0.5 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3..........................................................................0.305

g/cm3......................................................................... 8.44

Melting Point, °F......................................................2400 – 2460

°C......................................................1315 – 1350

Specific Heat, Btu/lb •°F.....................................................0.100

J/kg •°C........................................................... 419

Curie Temperature, °F........................................................... -150

°C.......................................................... -100

Permeability at 200 Oersted (15.9 kA/m).....................1.002

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.6

21 – 93°C, μm/m •°C............. 13.7

Thermal Conductivity, Btu • in/ft2• h•°F............................ 121

W/m•°C............................................17.5

Electrical Resistivity, ohm • circ mil/ft.............................. 370

μΩ•m...............................................0.615

Young's Modulus at RT, 103 ksi...............................................26

g/cm3......................................................................... 8.44

Melting Point, °F......................................................2400 – 2460

°C......................................................1315 – 1350

Specific Heat, Btu/lb •°F.....................................................0.100

J/kg •°C........................................................... 419

Curie Temperature, °F........................................................... -150

°C.......................................................... -100

Permeability at 200 Oersted (15.9 kA/m).....................1.002

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.6

21 – 93°C, μm/m •°C............. 13.7

Thermal Conductivity, Btu • in/ft2• h•°F............................ 121

W/m•°C............................................17.5

Electrical Resistivity, ohm • circ mil/ft.............................. 370

μΩ•m...............................................0.615

Young's Modulus at RT, 103 ksi...............................................26

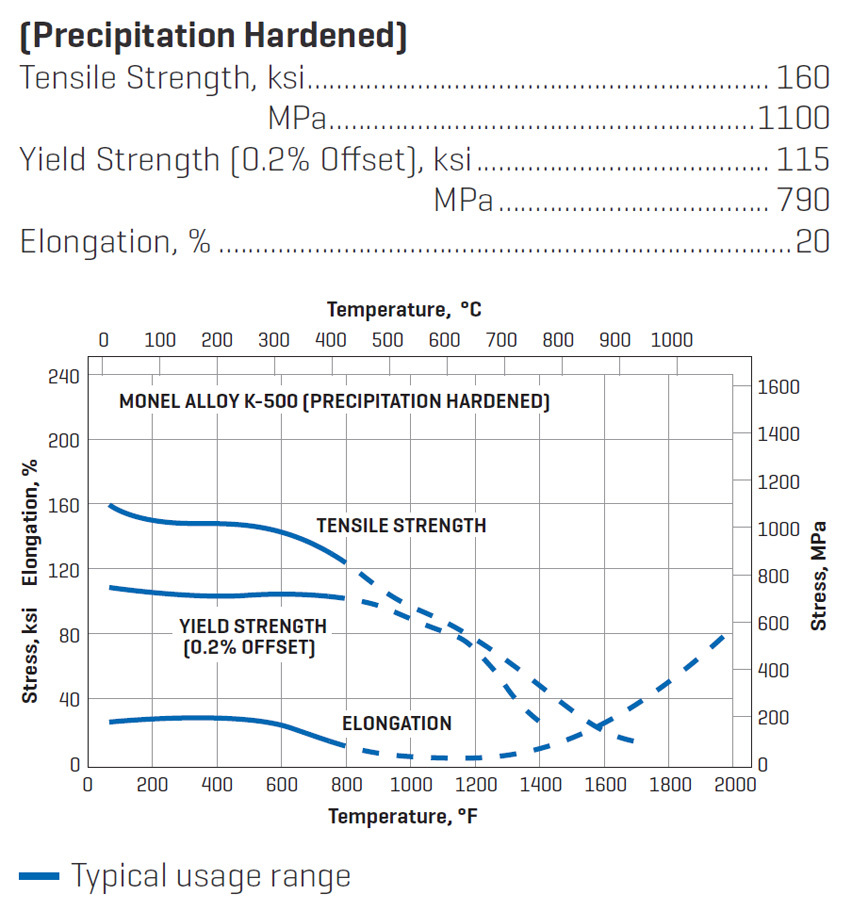

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message