Fuel cell vehicle air compressor air shaft

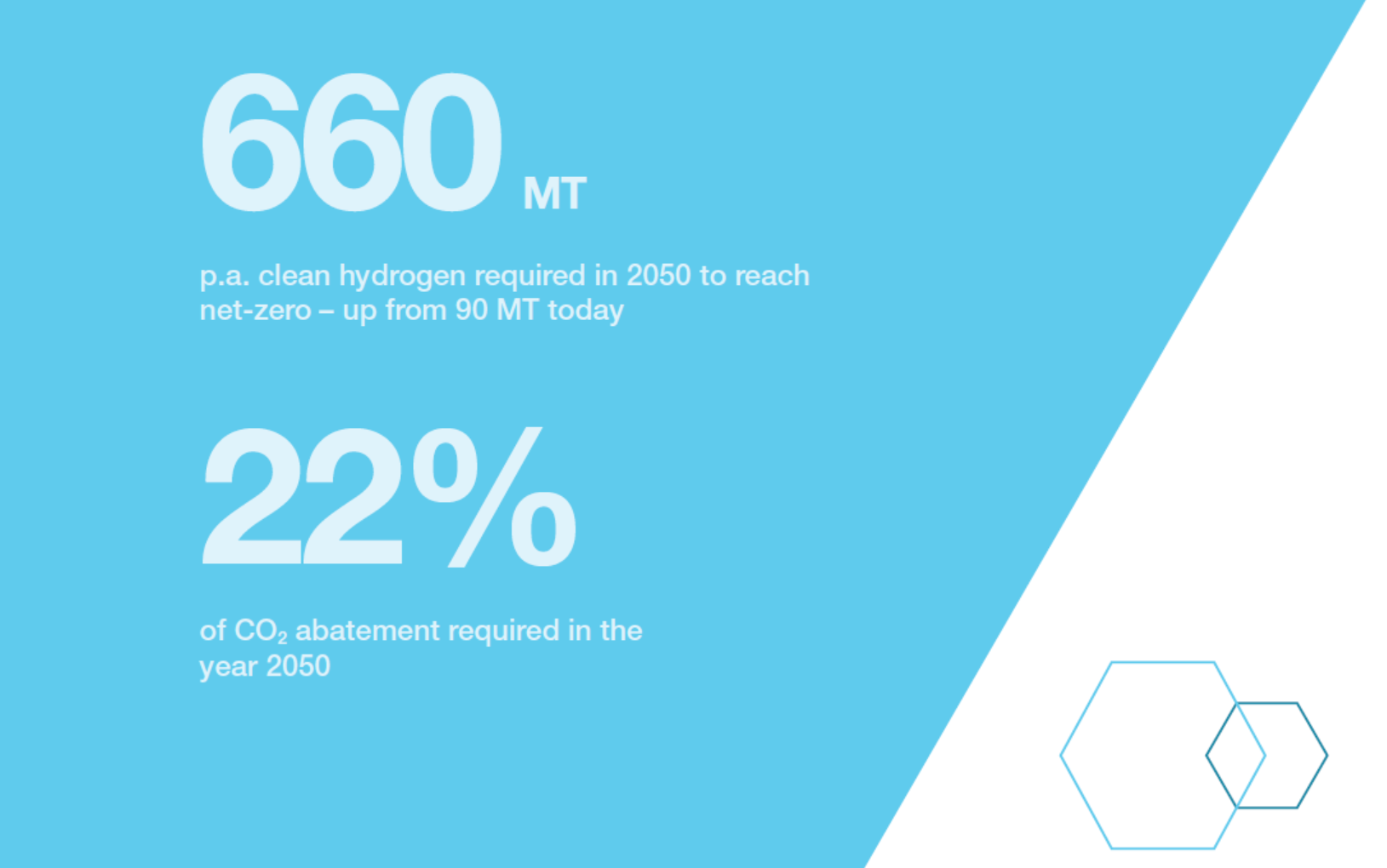

Hydrogen energy plays a key role in achieving a zero-carbon strategy. According to McKinsey's forecast, the application of hydrogen energy can reduce carbon emissions by 80G tons by 2050. Compared with other clean energy sources, hydrogen energy has significant advantages such as sustainability and scalability. By 2050, China will be the main body of the hydrogen market after Europe and the United States, and will account for 60% of the global volume. To achieve this goal, it is crucial to replace diesel vehicles with an annual fuel consumption of 50 billion liters by 2030 with green hydrogen. Because this will account for 13.3% of the total 2030 target, reducing carbon emissions by 100 million tons per year. Based on this, the central and local governments have intensively issued policy documents related to hydrogen energy in recent years to encourage the development of the entire hydrogen energy industry chain.

contact us Online message

Product Description

Fuel cell vehicle air compressor air shaft

1. Background introductionHydrogen energy plays a key role in achieving a zero-carbon strategy. According to McKinsey's forecast, the application of hydrogen energy can reduce carbon emissions by 80G tons by 2050. Compared with other clean energy sources, hydrogen energy has significant advantages such as sustainability and scalability. By 2050, China will be the main body of the hydrogen market after Europe and the United States, and will account for 60% of the global volume. To achieve this goal, it is crucial to replace diesel vehicles with an annual fuel consumption of 50 billion liters by 2030 with green hydrogen. Because this will account for 13.3% of the total 2030 target, reducing carbon emissions by 100 million tons per year. Based on this, the central and local governments have intensively issued policy documents related to hydrogen energy in recent years to encourage the development of the entire hydrogen energy industry chain. In 2019, hydrogen energy was written into the "Government Work Report" for the first time; in 2022, with the release of the "Medium and Long-Term Plan for the Development of Hydrogen Energy Industry (2021-2035)", hydrogen energy was identified as an important component of the future national energy system. The hydrogen energy industry has also been identified as a strategic emerging industry and a key development direction of the future industry as an important carrier for green and low-carbon transformation of some energy-using terminals. After the first batch of hydrogen fuel cell vehicle city demonstration clusters were approved in 2021, a boom in the hydrogen energy industry has sprung up everywhere. In January 2022, hydrogen energy was first mentioned in a Politburo document. Therefore, 2022 is considered to be the "first year" of hydrogen energy. It is expected that the hydrogen fuel cell vehicle-related industry will break through the trillion-dollar market, bringing profound technological changes to the industrial chain.

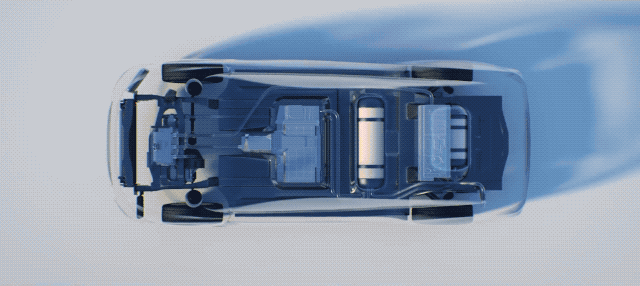

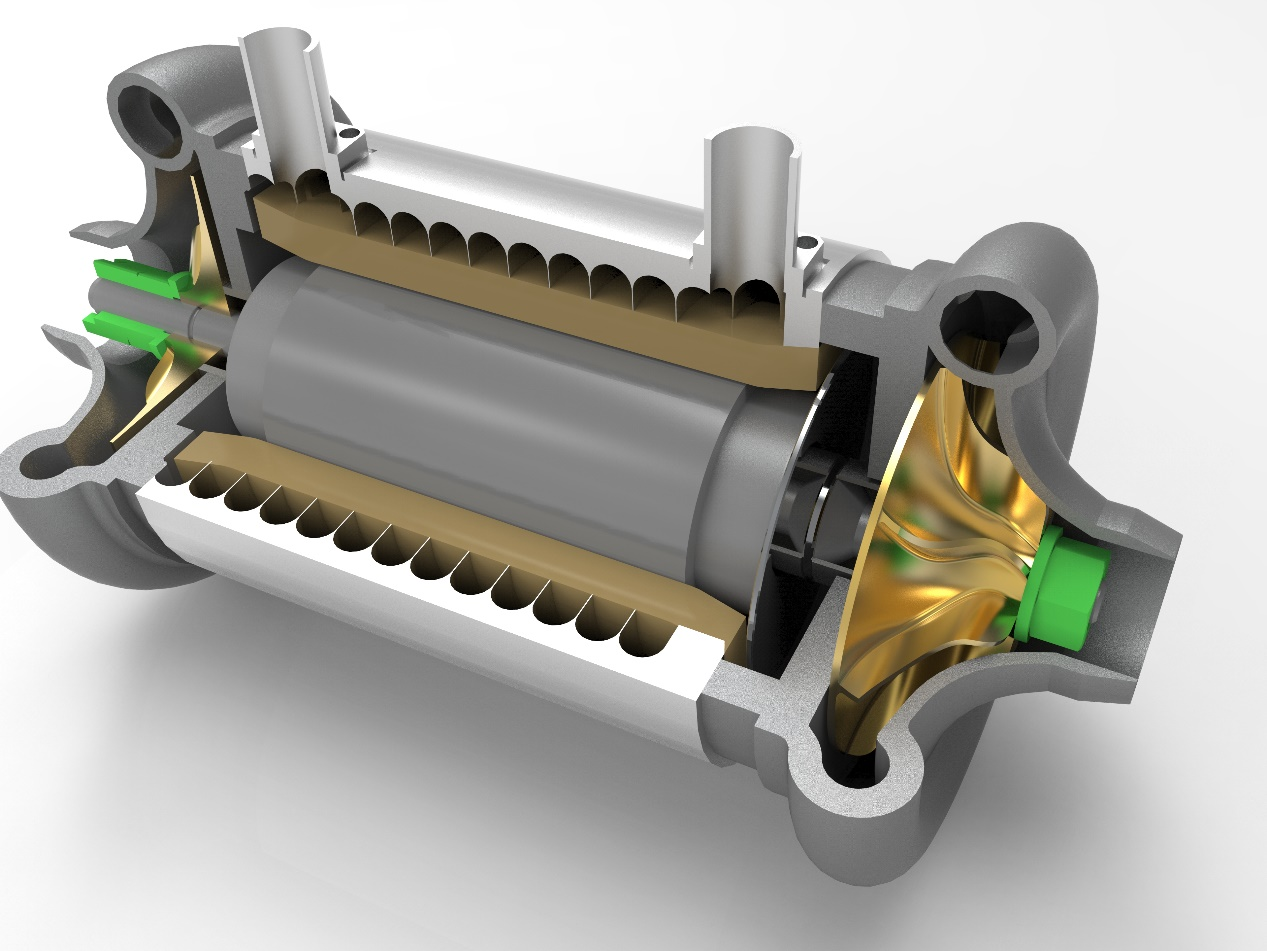

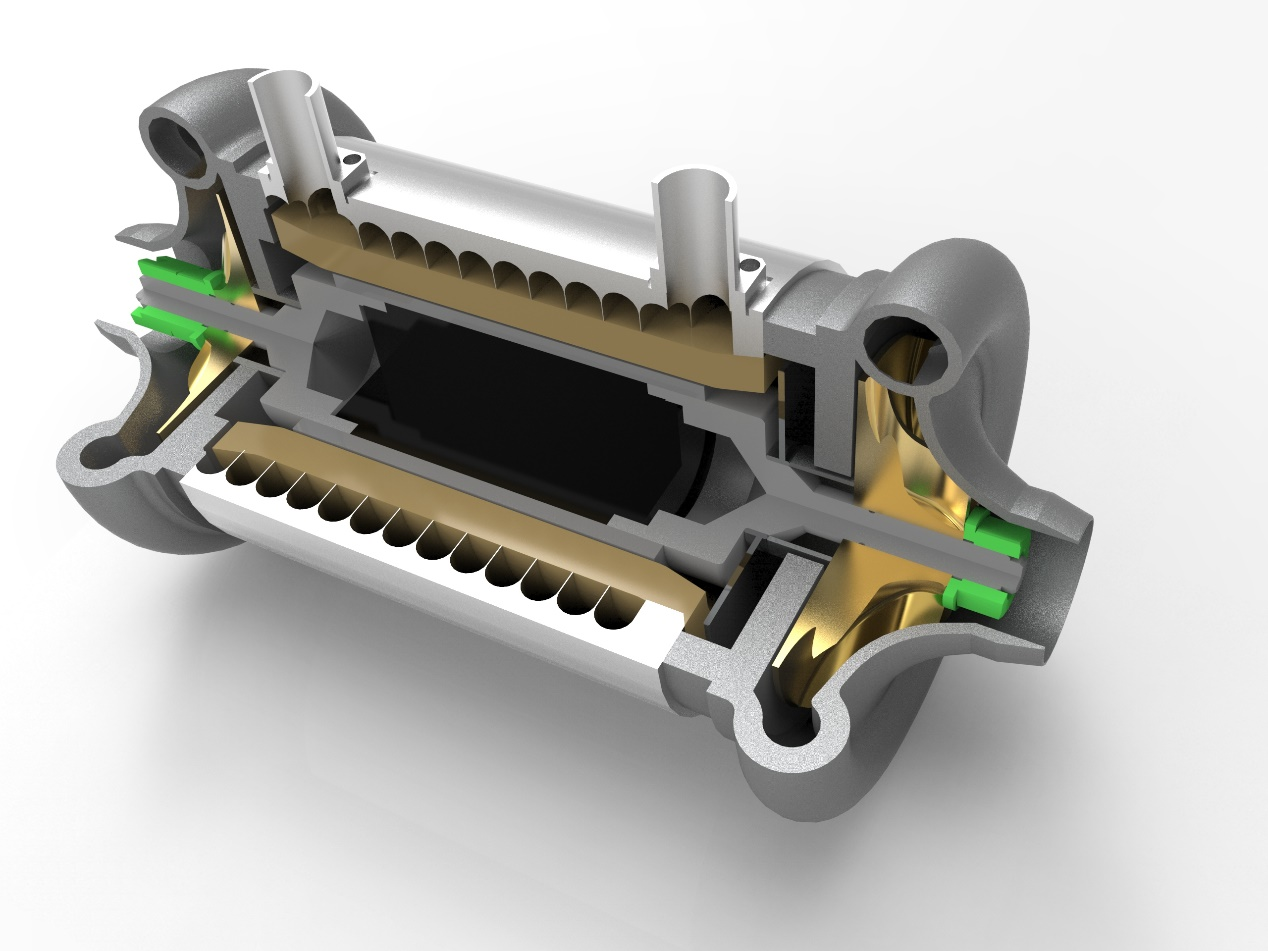

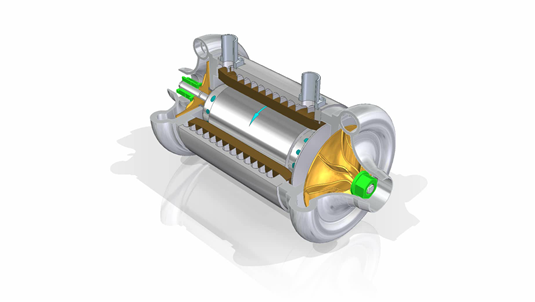

Air compressors are known as the "lungs" of hydrogen fuel cells, providing the clean air needed for the hydrogen fuel cell stack to react and are key components for the efficient operation of hydrogen fuel cell systems. The performance of the air compressor is closely related to the output power of the hydrogen fuel cell stack. High efficiency, small size, oil-free, adjustable flow, high pressure ratio and low noise are the characteristics of this type of air compressor. The centrifugal air compressor driven by the impeller type air flotation shaft is a high-performance air compressor with the above advantages. It has been favored by the industry in recent years and has developed rapidly. Among them, the air flotation shaft is the core component of this type of centrifugal air compressor. With more than ten years of industry accumulation in superalloy and metal precision machining, our company has developed air flotation shafts that meet various types and specifications of centrifugal air compressors. The products have won unanimous praise from leading companies in the industry.

2. The company teamShanghai Kangsheng Aviation Material Technology Co., Ltd. is located in Jiading Industrial Park, Shanghai. It is a high-tech enterprise specializing in special alloys such as superalloys, corrosion-resistant alloys, precision alloys, and titanium alloys, integrating the research and development, production and processing of special alloy materials. The company and Shanghai Jiaotong University jointly established the "Aerospace Superalloy Application R&D Center" and "Engineering Practice Education Center"; and jointly tackled key problems with the relevant research institutes of the Chinese Academy of Sciences, the Steel Research Institute, and Fushun Special Steel to improve the production process and adopt the vacuum duplex , triple process smelting, effectively remove low melting point impurities, non-ferrous elements and gases in the alloy, reduce non-metallic inclusions, improve the crystalline structure in the alloy, and significantly improve the performance of special alloy materials. The company has vacuum induction melting device, high vacuum heat treatment furnace, high-precision variable frequency leveling and slitting system device, high-precision horizontal CNC lathe, vertical machining center, high-precision cylindrical grinder, vertical/horizontal honing machine, slow walking Melting and precision processing equipment such as wire machine tools, spark CNC forming machine tools, as well as complete metallographic analysis and testing laboratories and measuring equipment. Our company has a professional and skilled team of engineers, which can provide customers with "delivered product" integrated services from material formulation research and development, alloy melting, and device precision machining to ensure the quality from raw materials to products and devices. The company's products have been used in aerospace, petroleum, petrochemical, electronics, nuclear energy industry, chemical industry, marine industry and other fields, and have been recognized by leading companies in the industry. Our company adheres to the concept of "professionalism, quality first, and continuous creation of value for customers", to meet customers' potential needs and long-term development, to provide personalized and customized solutions, and to grow together with customers, so it is deeply trusted by industry customers. .

In 2013, the company obtained the national-level "High-tech Enterprise" approved by the Shanghai Municipal Science and Technology Commission, and in 2015 was recognized as a "specialized, refined, and new" enterprise by the Shanghai Municipal Commission of Economy and Information Technology. The company has more than 20 patents, and the company's products have been recognized by the Shanghai Science and Technology Commission as a Class A project for the transformation of high-tech achievements for three consecutive years. In 2017, the company was listed on the New Third Board (code: 870665). Has obtained ISO9001 quality management system (2008), automotive quality management system (IATF16949), international aerospace quality management system (AS9100D), China weapons and equipment quality management system (GJB9001C) and other industry qualification certification.

(Company and plant equipment pictures)

3. Product description, performance indicators (finishness, mechanical properties, heat generation)

4. Product performance

| model | Specification | Material | roughness | Mechanical properties |

| - | - | - | - | - |

| - | - | - | - | - |

| - | - | - | - | - |

| - | - | - | - | - |

air

the

and

of

in

hydrogen

to

energy

industry

Related Products

Online message