Product Description

A nickel-base alloy solid solution strengthened with tungsten and molybdenum and precipitation hardened with titanium and aluminum. The alloy combines high strength with metallurgical stability, as demonstrated by excellent impact strength retention after long exposures at elevated temperatures. Good oxidation and corrosion resistance combined with high strength make the alloy useful in gas turbine blades and disc applications.

STANDARD PRODUCT FORMS

Forging billet and bar.

MAJOR SPECIFICATIONS

EMS 55477, EMS 73105, MSRR 7252, C50TF105, MTS 5013

LIMITING CHEMICAL COMPOSITION, %

Limiting

Ni ............Balance

Cr ......15.5 – 16.5

Co .....14.0 – 15.5

Mo ....2.75 – 3.25

W ......1.00 – 1.50

Ti ......4.75 – 5.25

Al ......2.25 – 2.75

C .......0.01 – 0.02

Zr ...0.025 – 0.05

B ......0.01 – 0.02

Ni ............Balance

Cr ......15.5 – 16.5

Co .....14.0 – 15.5

Mo ....2.75 – 3.25

W ......1.00 – 1.50

Ti ......4.75 – 5.25

Al ......2.25 – 2.75

C .......0.01 – 0.02

Zr ...0.025 – 0.05

B ......0.01 – 0.02

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3........................................................................0.292

g/cm3 .........................................................................8.08

Melting Range, °F ...................................................2180 – 2440

°C ...................................................1194 – 1338

Coefficient of Expansion, 70 – 200°F, 10-6 in/in • °F........6.8

21 – 93°C, µm/m • °C ..........12.24

g/cm3 .........................................................................8.08

Melting Range, °F ...................................................2180 – 2440

°C ...................................................1194 – 1338

Coefficient of Expansion, 70 – 200°F, 10-6 in/in • °F........6.8

21 – 93°C, µm/m • °C ..........12.24

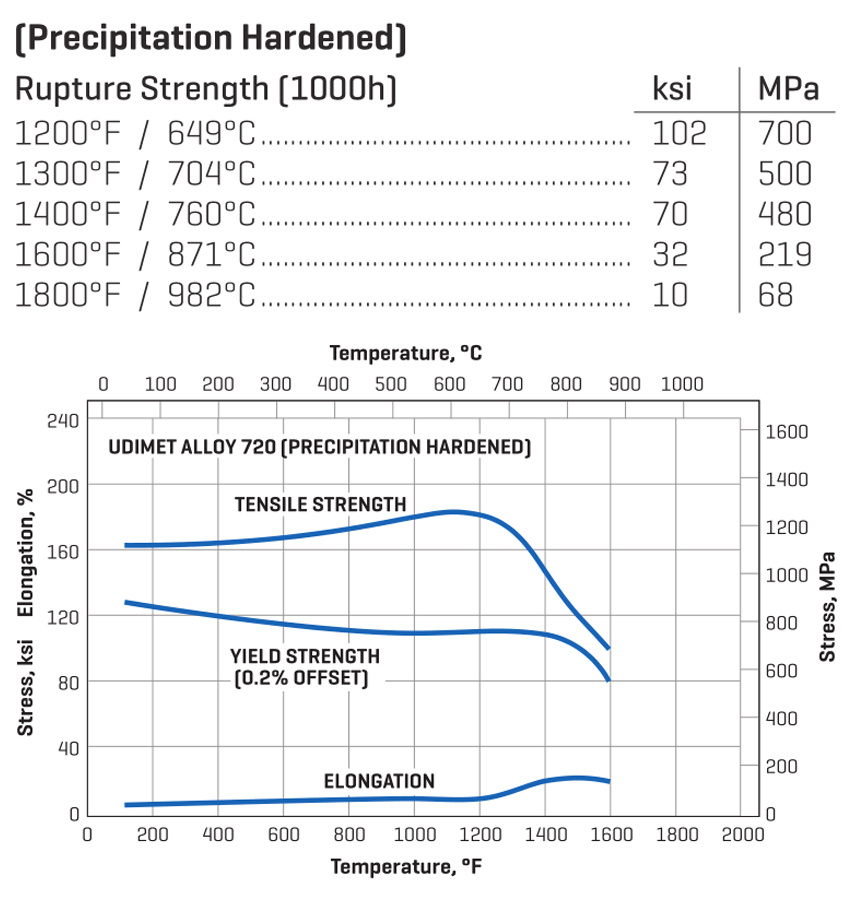

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

720

ndash

and

deg

in

with

strength

alloy

2.75

limiting

Related Products

Online message