Product Description

Commercially pure (99.6%) wrought nickel essentially the same as Nickel 200 but with a lower carbon content to prevent embrittlement by intergranular carbon at temperatures over 600°F (315°C). Lower carbon content

also reduces hardness, making Nickel 201 particularly suitable for cold-formed items.

also reduces hardness, making Nickel 201 particularly suitable for cold-formed items.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon and wire.

stock, hexagon and wire.

MAJOR SPECIFICATIONS

UNS N02201

BS 3072 – 3074 (NA12)

ASTM B 160 – B 163, B 366,

B 725, B 730, B 751,

B 775, B 829

ASME SB-160 – SB-163,

SB-366, SB-725, SB-730,

SB-751, SB-775, SB-829

ASME Code Case 2249

SAE AMS 5553

DIN 17740, 17750 – 17754

Werkstoff Nr. 2.4061, 2.4068

VdTÜV 345

ISO 6207, 6208, 9723 – 9725

BS 3072 – 3074 (NA12)

ASTM B 160 – B 163, B 366,

B 725, B 730, B 751,

B 775, B 829

ASME SB-160 – SB-163,

SB-366, SB-725, SB-730,

SB-751, SB-775, SB-829

ASME Code Case 2249

SAE AMS 5553

DIN 17740, 17750 – 17754

Werkstoff Nr. 2.4061, 2.4068

VdTÜV 345

ISO 6207, 6208, 9723 – 9725

LIMITING CHEMICAL COMPOSITION, %

Nia..........99.0 min.

Cu........0.25 max.

Fe.........0.40 max.

aPlus Co.

Mn........0.35 max.

C...........0.02 max.

Si..........0.35 max.

S...........0.01 max.

Cu........0.25 max.

Fe.........0.40 max.

aPlus Co.

Mn........0.35 max.

C...........0.02 max.

Si..........0.35 max.

S...........0.01 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.321

g/cm3......................................................................... 8.89

Melting Range, °F....................................................2615 – 2635

°C....................................................1435 – 1446

Specific Heat, Btu/lb•°F.....................................................0.109

J/kg•°C............................................................ 456

Curie Temperature, °F............................................................ 680

°C............................................................ 360

Permeability......................................................... Ferromagnetic

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.3

21 – 93°C, μm/m • °C............. 13.1

Thermal Conductivity, Btu • in/ft2•h•°F............................ 550

W/m • °C.......................................... 79.3

Electrical Resistivity, ohm •circ mil/ft...................................51

μΩ•m...............................................0.085

g/cm3......................................................................... 8.89

Melting Range, °F....................................................2615 – 2635

°C....................................................1435 – 1446

Specific Heat, Btu/lb•°F.....................................................0.109

J/kg•°C............................................................ 456

Curie Temperature, °F............................................................ 680

°C............................................................ 360

Permeability......................................................... Ferromagnetic

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.3

21 – 93°C, μm/m • °C............. 13.1

Thermal Conductivity, Btu • in/ft2•h•°F............................ 550

W/m • °C.......................................... 79.3

Electrical Resistivity, ohm •circ mil/ft...................................51

μΩ•m...............................................0.085

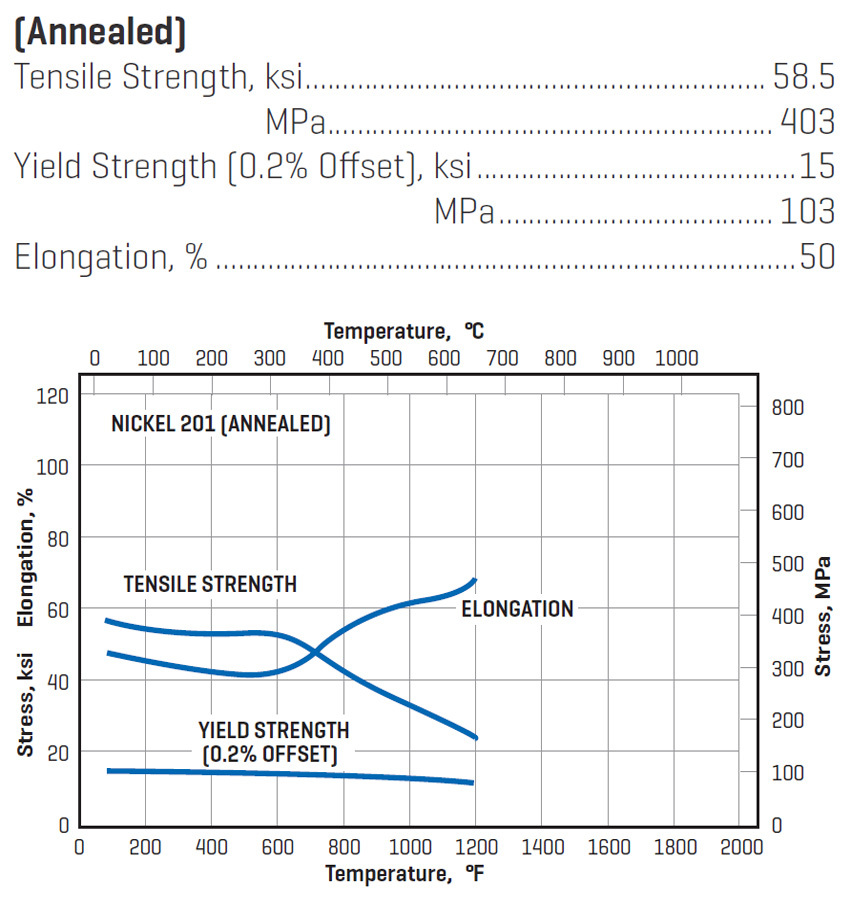

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

nickel

deg

ndash

bull

max.

in

carbon

bar

thermal

Related Products

Online message