Product Description

A nickel-chromium-cobalt-molybdenum alloy with an exceptional combination of metallurgical stability, strength and oxidation resistance at high temperatures. Resistance to oxidation is enhanced by an aluminum addition. The

alloy also resists a wide range of corrosive aqueous environments. Used in gas turbines for combustion cans, ducting and transition liners; petrochemical processing; heat-treating equipment; and in nitric acid production.

alloy also resists a wide range of corrosive aqueous environments. Used in gas turbines for combustion cans, ducting and transition liners; petrochemical processing; heat-treating equipment; and in nitric acid production.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon, wire and extruded section.

stock, hexagon, wire and extruded section.

MAJOR SPECIFICATIONS

UNS N06617

ASTM B 166, B 168, B 546,

B 564

ASME SB-166, SB-168, SB-546,

SB-564

SAE AMS 5887 – 5889

ASME Code Cases 1956,

1982

Werkstoff Nr. 2.4663a

VdTÜV 485

ISO 6207, 6208, 9724

DIN 17744, 17750-17754

ASTM B 166, B 168, B 546,

B 564

ASME SB-166, SB-168, SB-546,

SB-564

SAE AMS 5887 – 5889

ASME Code Cases 1956,

1982

Werkstoff Nr. 2.4663a

VdTÜV 485

ISO 6207, 6208, 9724

DIN 17744, 17750-17754

LIMITING CHEMICAL COMPOSITION, %

Ni...........44.5 min.

Cr.......20.0 – 24.0

Co......10.0 – 15.0

Mo....... 8.0 – 10.0

Al............0.8 – 1.5

C........0.05 – 0.15

Fe........... 3.0 max.

Mn.......... 1.0 max.

Si............ 1.0 max.

S........ 0.015 max.

Ti............ 0.6 max.

Cu.......... 0.5 max.

B........ 0.006 max.

Cr.......20.0 – 24.0

Co......10.0 – 15.0

Mo....... 8.0 – 10.0

Al............0.8 – 1.5

C........0.05 – 0.15

Fe........... 3.0 max.

Mn.......... 1.0 max.

Si............ 1.0 max.

S........ 0.015 max.

Ti............ 0.6 max.

Cu.......... 0.5 max.

B........ 0.006 max.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.302

g/cm3......................................................................... 8.36

Melting Range, °F....................................................2430 – 2510

°C....................................................1330 – 1380

Specific Heat, Btu/lb•°F.....................................................0.100

J/kg•°C............................................................ 419

Coefficient of Expansion, 78 – 200°F, 10-6 in/in •°F........6.4

20 – 100°C, μm/m •°C.......... 11.6

Thermal Conductivity, Btu • in/ft2•h•°F...............................94

W/m •°C........................................... 13.6

Electrical Resistivity, ohm •circ mil/ft................................ 736

μΩ•m................................................. 1.22

g/cm3......................................................................... 8.36

Melting Range, °F....................................................2430 – 2510

°C....................................................1330 – 1380

Specific Heat, Btu/lb•°F.....................................................0.100

J/kg•°C............................................................ 419

Coefficient of Expansion, 78 – 200°F, 10-6 in/in •°F........6.4

20 – 100°C, μm/m •°C.......... 11.6

Thermal Conductivity, Btu • in/ft2•h•°F...............................94

W/m •°C........................................... 13.6

Electrical Resistivity, ohm •circ mil/ft................................ 736

μΩ•m................................................. 1.22

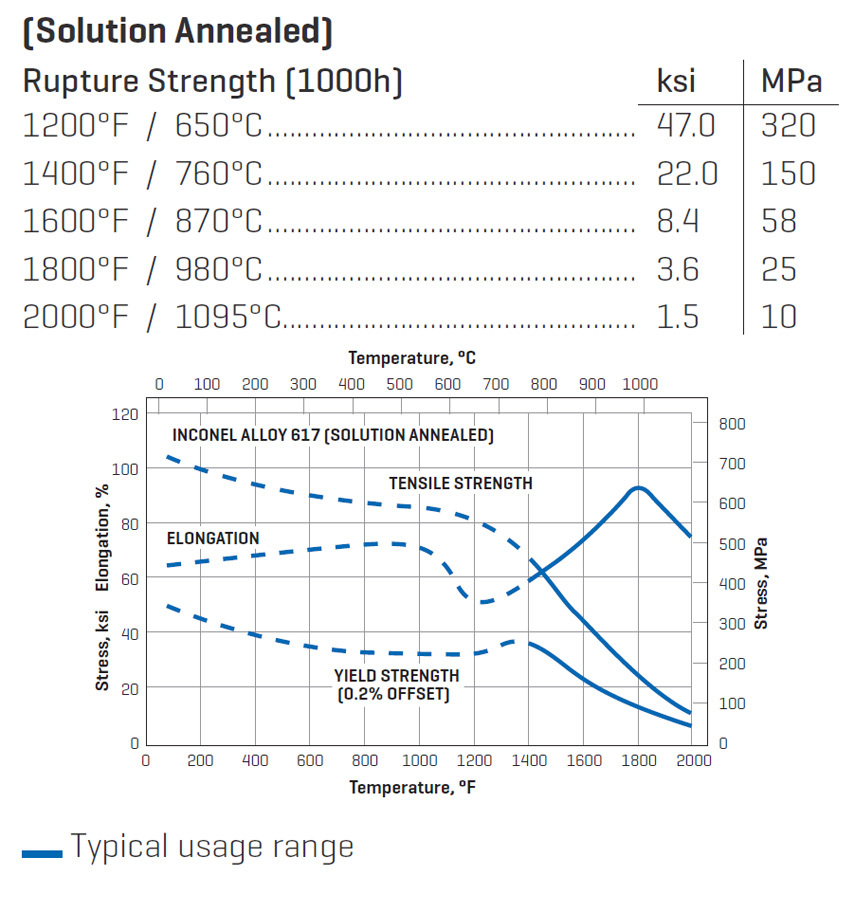

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message