Product Description

A nickel-chromium-molybdenum alloy with an addition of niobium that acts with the molybdenum to stiffen the alloy's matrix and thereby provide high strength without a strengthening heat treatment. The alloy resists a wide range of severely corrosive environmentsand is especially resistant to pitting and crevice corrosion. Used in chemical processing,aerospace and marine engineering, pollutioncontrol equipment and nuclear reactors.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging

stock, hexagon, wire and extruded section.

stock, hexagon, wire and extruded section.

MAJOR SPECIFICATIONS

UNS N06625

ASTM B 366, B 443, B 444,

B 446, B 564, B 704,

B 705, B 751, B 775, B 829

ASME SB-366, SB-443, SB-444,

SB-446, SB-564, SB-704,

SB-705, SB-751, SB-775,

SB-829

ASME Code Case 1935

SAE AMS 5581, 5599, 5666,

5837, 5869, MAM 5599

BS 3072, 3074, 3076 (NA21)

DIN 17744, 17750 – 17754

Werkstoff Nr. 2.4856

NACE MR-0175/ISO 15156

VdTÜV 499, EN 10095

ISO NW6625, ISO 6207,

6208, 9723 – 9725, 4955A

ASTM B 366, B 443, B 444,

B 446, B 564, B 704,

B 705, B 751, B 775, B 829

ASME SB-366, SB-443, SB-444,

SB-446, SB-564, SB-704,

SB-705, SB-751, SB-775,

SB-829

ASME Code Case 1935

SAE AMS 5581, 5599, 5666,

5837, 5869, MAM 5599

BS 3072, 3074, 3076 (NA21)

DIN 17744, 17750 – 17754

Werkstoff Nr. 2.4856

NACE MR-0175/ISO 15156

VdTÜV 499, EN 10095

ISO NW6625, ISO 6207,

6208, 9723 – 9725, 4955A

LIMITING CHEMICAL COMPOSITION, %

Ni...........58.0 min.

Cr.......20.0 – 23.0

Mo....... 8.0 – 10.0

Nba....3.15 – 4.15

aPlus Co.

Fe........... 5.0 max.

C...........0.10 max.

Mn........0.50 max.

Si..........0.50 max.

S........ 0.015 max.

Al..........0.40 max.

Ti..........0.40 max.

P......... 0.015 max.

Cob......... 1.0 max.

bIf determined.

Cr.......20.0 – 23.0

Mo....... 8.0 – 10.0

Nba....3.15 – 4.15

aPlus Co.

Fe........... 5.0 max.

C...........0.10 max.

Mn........0.50 max.

Si..........0.50 max.

S........ 0.015 max.

Al..........0.40 max.

Ti..........0.40 max.

P......... 0.015 max.

Cob......... 1.0 max.

bIf determined.

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.305

g/cm3......................................................................... 8.44

Melting Range, °F....................................................2350 – 2460

°C....................................................1290 – 1350

Specific Heat, Btu/lb•°F.....................................................0.098

J/kg•°C............................................................ 410

Curie Temperature, °F........................................................<-320

°C........................................................<-196

Permeability at 200 Oersted (15.9 kA/m)................... 1.0006

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.1

21 – 93°C, μm/m • °C............. 12.8

Thermal Conductivity, Btu • in/ft2•h•°F...............................68

W/m • °C.............................................9.8

Electrical Resistivity, ohm •circ mil/ft................................ 776

μΩ•m................................................. 1.29

g/cm3......................................................................... 8.44

Melting Range, °F....................................................2350 – 2460

°C....................................................1290 – 1350

Specific Heat, Btu/lb•°F.....................................................0.098

J/kg•°C............................................................ 410

Curie Temperature, °F........................................................<-320

°C........................................................<-196

Permeability at 200 Oersted (15.9 kA/m)................... 1.0006

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.1

21 – 93°C, μm/m • °C............. 12.8

Thermal Conductivity, Btu • in/ft2•h•°F...............................68

W/m • °C.............................................9.8

Electrical Resistivity, ohm •circ mil/ft................................ 776

μΩ•m................................................. 1.29

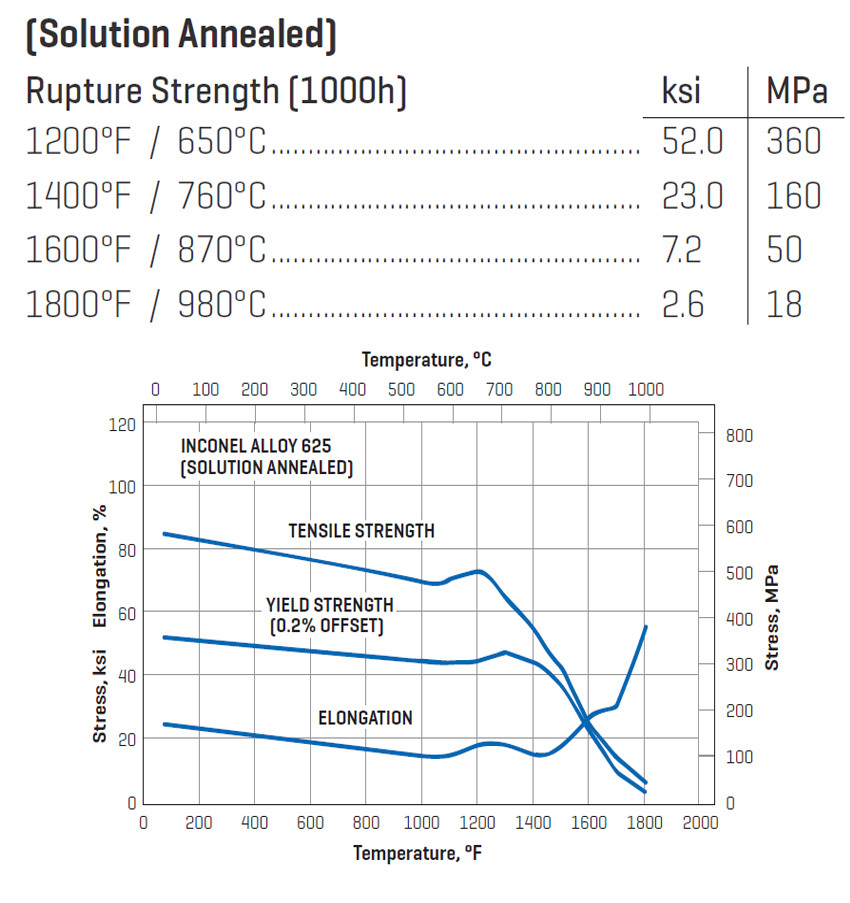

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message