Product Description

An alloy designed for outstanding corrosionresistance in a wide range of severe environments. The alloy is used in the most severe environments encountered in chemical processing, pollution control, pulp and paper production, and treatment of industrial and municipal wastes. Chemical processing uses include heat exchangers, reaction

vessels, evaporators and transfer piping. Air pollution control applications are stack liners,ducts, dampers, scrubbers, stack-gas reheaters,fans and housings.

vessels, evaporators and transfer piping. Air pollution control applications are stack liners,ducts, dampers, scrubbers, stack-gas reheaters,fans and housings.

STANDARD PRODUCT FORMS

Pipe, tube, sheet, strip, plate, round bar, forging stock,

hexagon and wire.

hexagon and wire.

MAJOR SPECIFICATIONS

UNS N06686

ASTM B 163, B 462, B 564,

B 574, B 575, B 619, B 622,

B 626, B 751, B 775, B 829,

B 906, F 467, F 467M, F 468,

F 468M

DIN 17744, 17750 – 17754

Werkstoff Nr. 2.4606

ASME Code Case 2198

ASME SB-163, SB-564,

SB-574, SB-575, SB-619,

SB-622, SB-626, SB-751,

SB-775, SB-829, SB-906

VdTÜV 515

NACE MR-0175/ISO 15156

SAE/AMS J2295, J2271, J2655,

J2280, J2485

ASTM B 163, B 462, B 564,

B 574, B 575, B 619, B 622,

B 626, B 751, B 775, B 829,

B 906, F 467, F 467M, F 468,

F 468M

DIN 17744, 17750 – 17754

Werkstoff Nr. 2.4606

ASME Code Case 2198

ASME SB-163, SB-564,

SB-574, SB-575, SB-619,

SB-622, SB-626, SB-751,

SB-775, SB-829, SB-906

VdTÜV 515

NACE MR-0175/ISO 15156

SAE/AMS J2295, J2271, J2655,

J2280, J2485

LIMITING CHEMICAL COMPOSITION, %

Cr.......19.0 – 23.0

Mo..... 15.0 – 17.0

W............3.0 – 4.4

Ti.......0.02 – 0.25

Fe........... 1.0 max.

C...........0.01 max.

Mn........0.75 max.

S...........0.02 max.

Si..........0.08 max.

P............0.04 max.

Ni............. Balance

Mo..... 15.0 – 17.0

W............3.0 – 4.4

Ti.......0.02 – 0.25

Fe........... 1.0 max.

C...........0.01 max.

Mn........0.75 max.

S...........0.02 max.

Si..........0.08 max.

P............0.04 max.

Ni............. Balance

PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3.........................................................................0.315

g/cm3......................................................................... 8.73

Melting Range, °F....................................................2440 – 2516

°C....................................................1338 – 1380

Specific Heat, Btu/lb•°F.....................................................0.089

J/kg•°C............................................................ 373

Permeability at 200 Oersted (15.9 kA/m).....................1.001

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F..... 6.67

20 – 100°C, μm/m • °C........11.97

Electrical Resistivity, ohm •circ mil/ft.............................744.4

μΩ•m...............................................1.237

g/cm3......................................................................... 8.73

Melting Range, °F....................................................2440 – 2516

°C....................................................1338 – 1380

Specific Heat, Btu/lb•°F.....................................................0.089

J/kg•°C............................................................ 373

Permeability at 200 Oersted (15.9 kA/m).....................1.001

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F..... 6.67

20 – 100°C, μm/m • °C........11.97

Electrical Resistivity, ohm •circ mil/ft.............................744.4

μΩ•m...............................................1.237

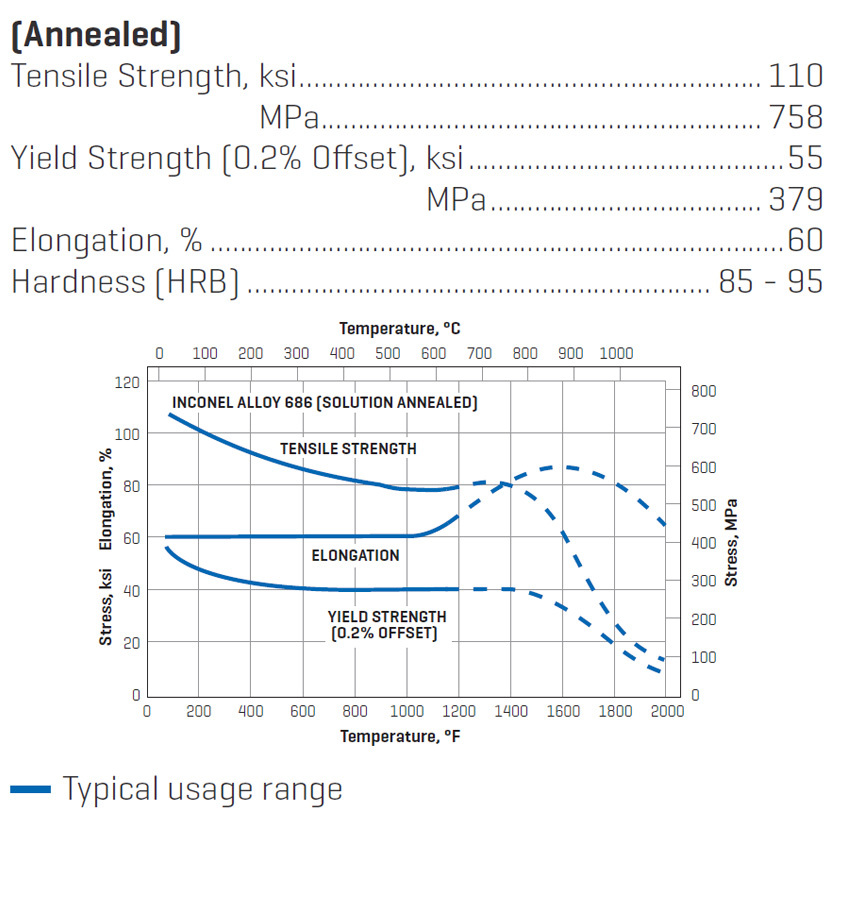

TYPICAL MECHANICAL PROPERTIES

previous

next

previous

next

Key words:

Related Products

Online message